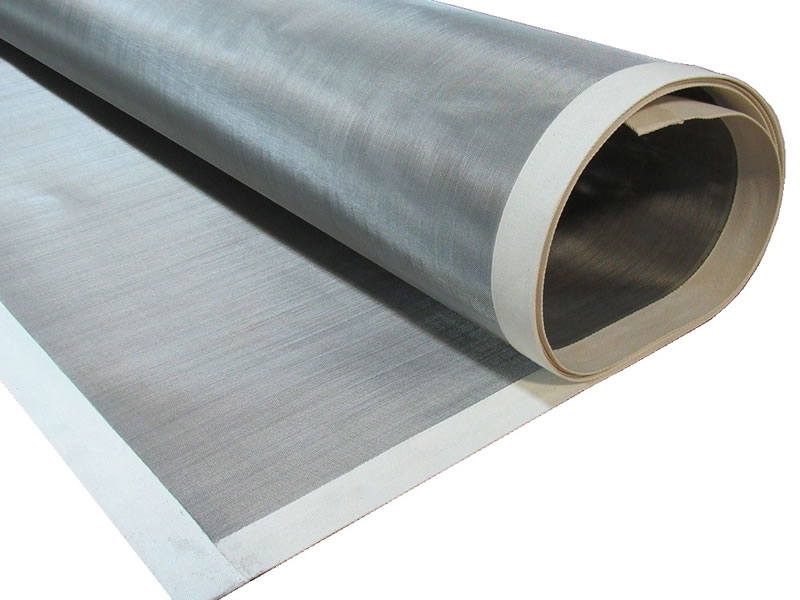

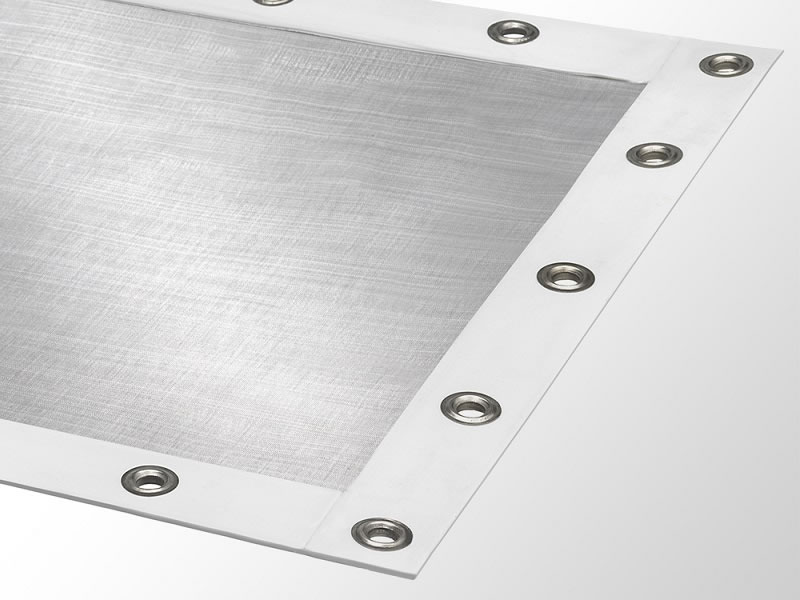

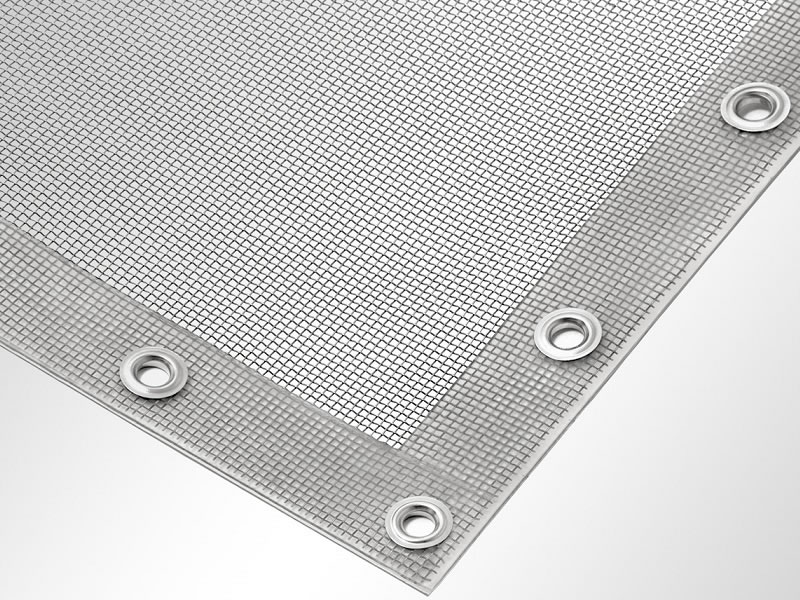

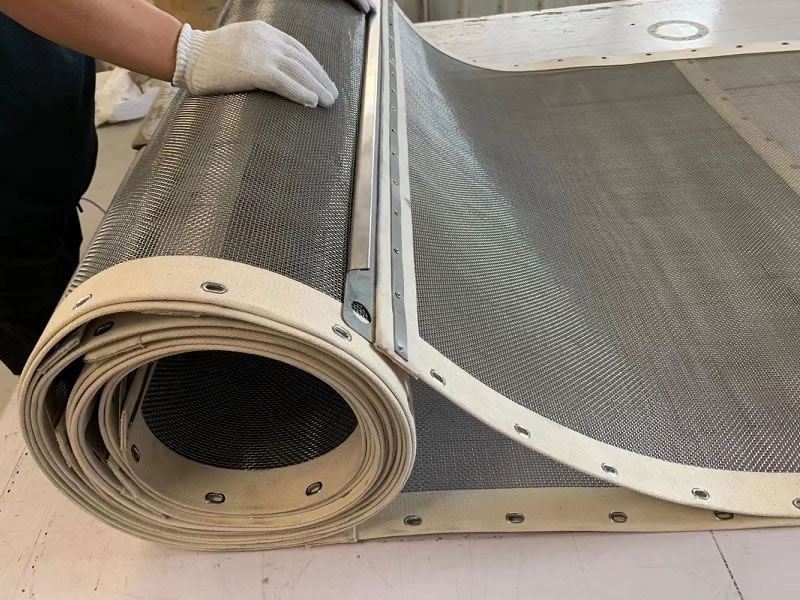

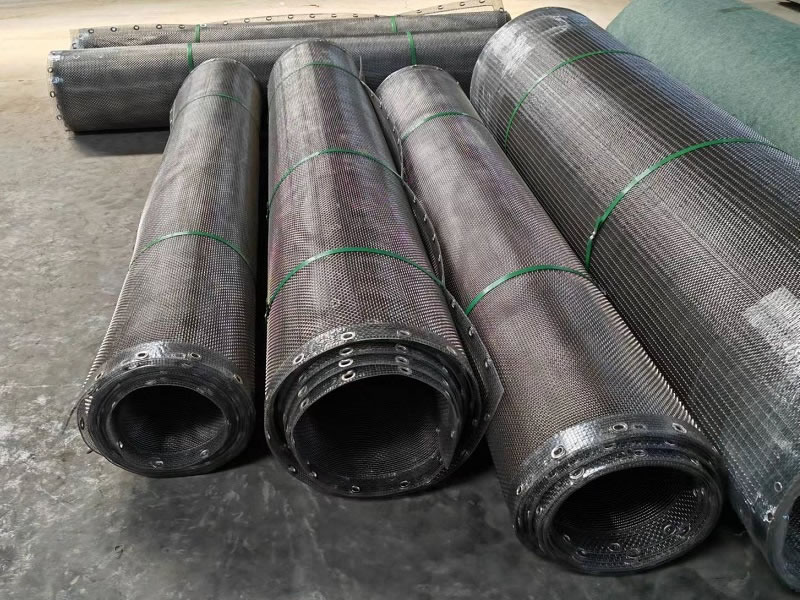

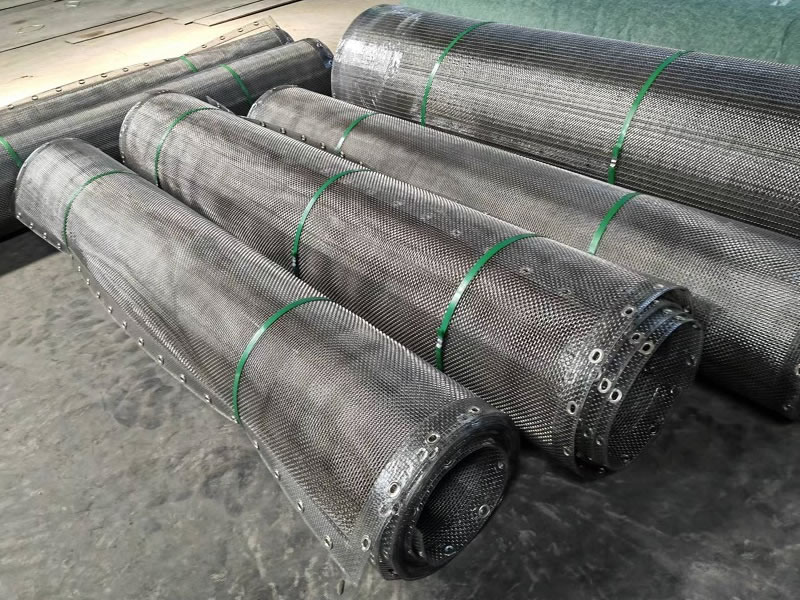

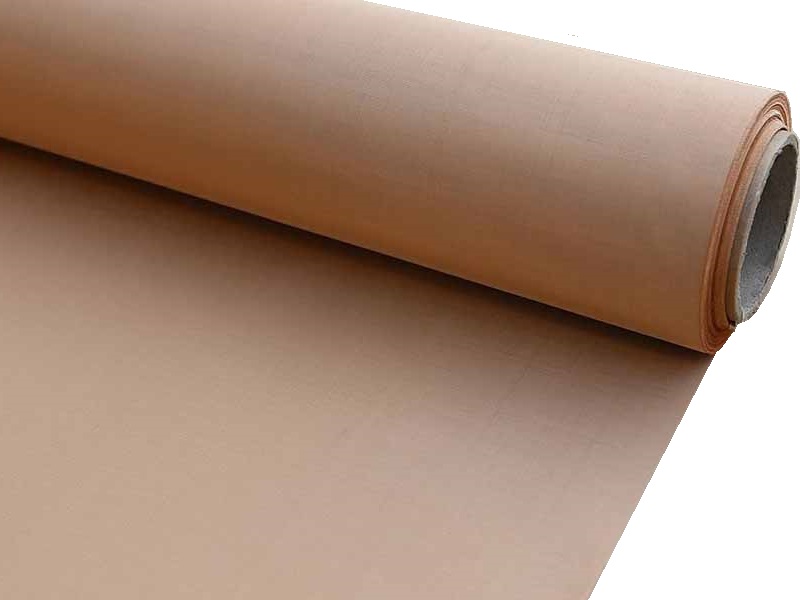

Grommet screen is a sieve screen used in mineral processing machines. The edges are reinforced in 2 ways. One is using strong reinforced strips for reinforcement, generally white and black strips are available for your option. Generally, reinforced strips are made of PU, canvas, silica gel ,etc. The other is by folding the edges of woven wire mesh as reinforced edges. When the working temperature is higher than 80 °C, PU strips cannot be used. So, folding the edges of woven wire mesh as reinforced edges is highly recommended.

Introduction:

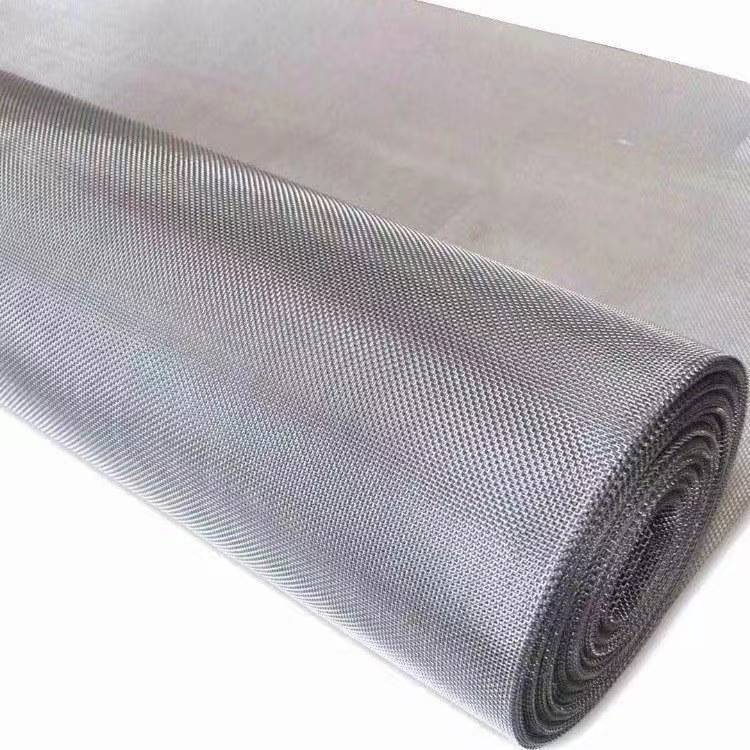

Mesh Material: stainless steel 304, 304L, 316, 316L

Edge material: Generally reinforced strips are made of PU, canvas, silica gel, etc.

Mesh type: woven mesh

Mesh count: 14–230

Wire diameter: 0.0014–0.0090 inch

Open area: 46.0%–76.4%

Features:

Excellent corrosion resistance

Good acid and alkali resistance

Great UV resistance

High toughness and strength

Simplified installation process

Application:

Filtration in Chemical Industry, Filtration in Plastic & Plastic Recycling Industry, Filtration in Pharmaceutical Industry, Filtration in Food Industry, Filtration in Ceramic Industry.

Specifications:

| Grommet Screen Specifications | ||||

| Objet | Taille des mailles | Wire Size (in.) | Microns | Open Area % |

| 1 | 14 | 0.009 | 1580 | 76.4 |

| 2 | 16 | 0.009 | 1360 | 73.3 |

| 3 | 18 | 0.009 | 1180 | 70.2 |

| 4 | 20 | 0.009 | 1040 | 67.2 |

| 5 | 22 | 0.0075 | 964 | 69.7 |

| 6 | 24 | 0.0075 | 868 | 67.2 |

| 7 | 26 | 0.0075 | 786 | 64.8 |

| 8 | 28 | 0.0075 | 716 | 62.4 |

| 9 | 30 | 0.0065 | 681 | 64.8 |

| 10 | 32 | 0.0065 | 630 | 62.7 |

| 11 | 34 | 0.0065 | 582 | 60.7 |

| 12 | 36 | 0.0065 | 541 | 58.7 |

| 13 | 38 | 0.0065 | 503 | 56.7 |

| 14 | 40 | 0.0065 | 470 | 54.8 |

| 15 | 42 | 0.0055 | 465 | 59.1 |

| 16 | 44 | 0.0055 | 437 | 57.5 |

| 17 | 46 | 0.0055 | 411 | 55.8 |

| 18 | 48 | 0.0055 | 388 | 54.2 |

| 19 | 50 | 0.0055 | 368 | 52.5 |

| 20 | 52 | 0.0055 | 348 | 51 |

| 21 | 54 | 0.0055 | 330 | 49.4 |

| 22 | 58 | 0.0045 | 323 | 54.6 |

| 23 | 60 | 0.0045 | 310 | 53.3 |

| 24 | 62 | 0.0045 | 295 | 51.7 |

| 25 | 64 | 0.0045 | 281 | 50.7 |

| 26 | 70 | 0.0037 | 269 | 54.9 |

| 27 | 72 | 0.0037 | 259 | 53.8 |

| 28 | 74 | 0.0037 | 249 | 52.7 |

| 29 | 76 | 0.0037 | 241 | 51.7 |

| 30 | 78 | 0.0037 | 231 | 50.6 |

| 31 | 80 | 0.0037 | 224 | 49.6 |

| 32 | 84 | 0.0035 | 213 | 49.8 |

| 33 | 88 | 0.0035 | 201 | 47.9 |

| 34 | 90 | 0.0035 | 193 | 46.9 |

| 35 | 94 | 0.0035 | 180 | 45 |

| 36 | 105 | 0.003 | 165 | 46.9 |

| 37 | 120 | 0.0025 | 147 | 48.8 |

| 38 | 145 | 0.0022 | 119 | 46.4 |

| 39 | 165 | 0.0019 | 107 | 47.1 |

| 40 | 200 | 0.0016 | 86 | 46.2 |

| 41 | 230 | 0.0014 | 74 | 46 |