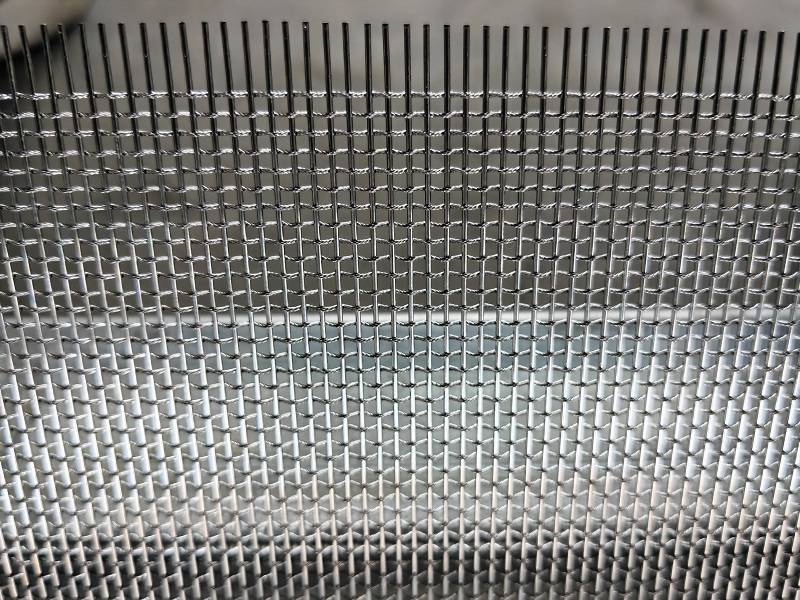

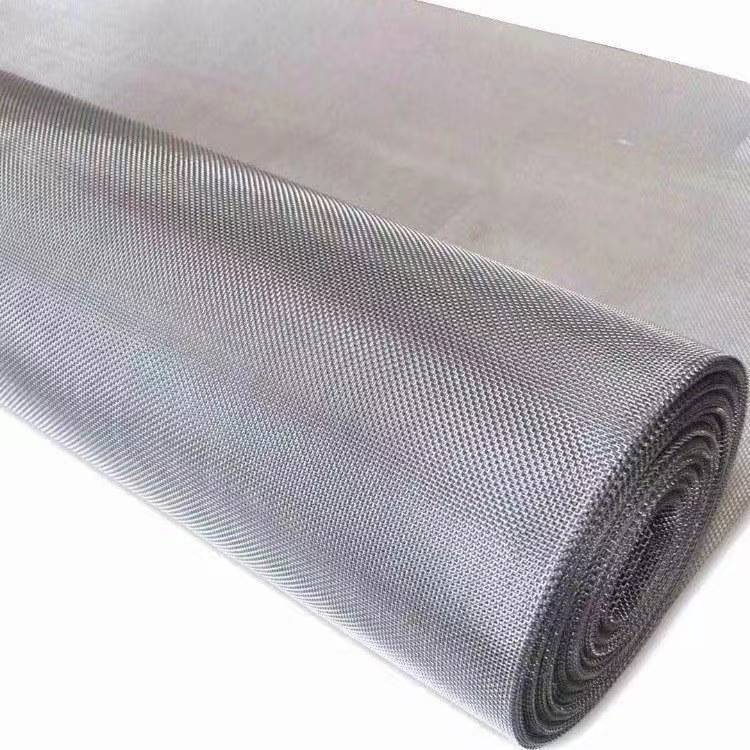

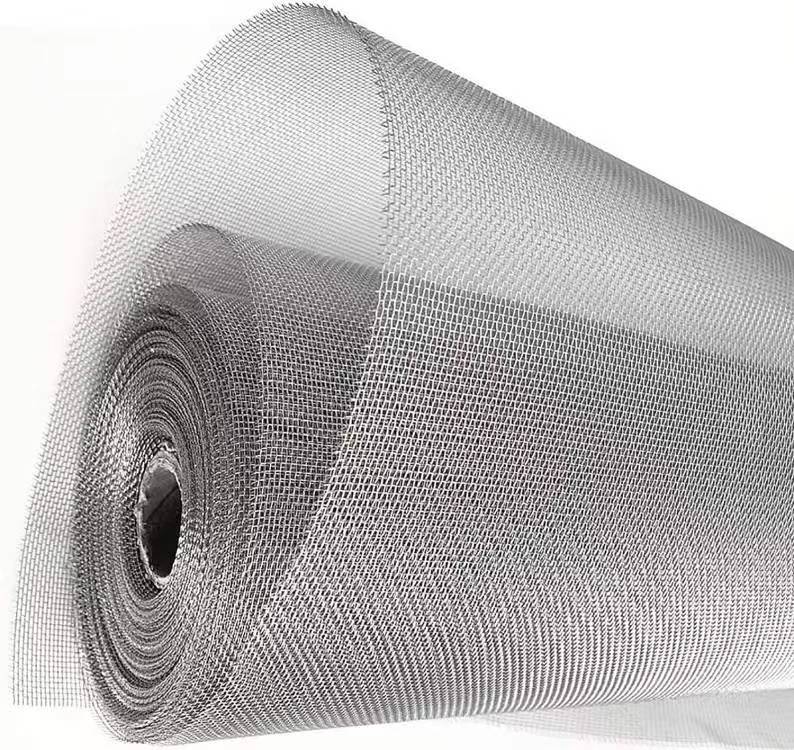

Foaming furnace mesh belt is also known as stainless steel wire rope conveyor belt. It is designed and manufactured for applications like foaming furnace channels. This mesh belt is made of ropes and rods with reinforced edges for direct rolling operation. We weave and supply many rolls to our clients in the XPE foaming furnace line.

Introduction:

Material: SS304, SS316, SS309, etc.

Rod diameter (a): 0.4 mm – 3.0 mm

Cable wire diameter (b): 0.5 mm – 3.0 mm

Rod pitch (c): 1.0 mm – 12.0 mm

Cable wire pitch (d): 0.5 mm – 12.7 mm

Width: 1.05 m – 6.5 m

Length: 30.0 m – 90.0 m

Selvage: Loop edge or cut edge

Features:

Smooth and flat surface & easy to clean

High temperature resistance & corrosion resistance

Abrasion resistant & high strength

Suitable for heat distributor opening

Easy to install & simple to run

Long working life and short downtime

Application:

Plastic, leather, non-woven and other machinery foaming furnace in the conveyor belt

Heating and drying of wood or wood chips, high strength filtration and protective or explosion-proof industries