JD Hardware Wire Mesh Co., Ltd offers the Stainless Steel Pleated Filter Cartridge Element, a versatile solution for sectors like biomedical pure water production, beverage processing, biochemical water treatment, and environmental protection. Available in various standard diameters, lengths, and grades, these elements ensure compatibility with industry standards and seamless integration into existing systems. Additionally, JD Hardware provides customization options to meet specific requirements.

The innovative pleated design of the product increases surface area, boosting flow rates, reducing pressure drops, and prolonging maintenance intervals. They are characterized by minimal adsorption, no medium shedding, leak-proof performance, and resistance to a wide range of chemicals, including acids, alkalis, and corrosives. Their easy-to-clean nature and backflushing capability enhance their practicality.

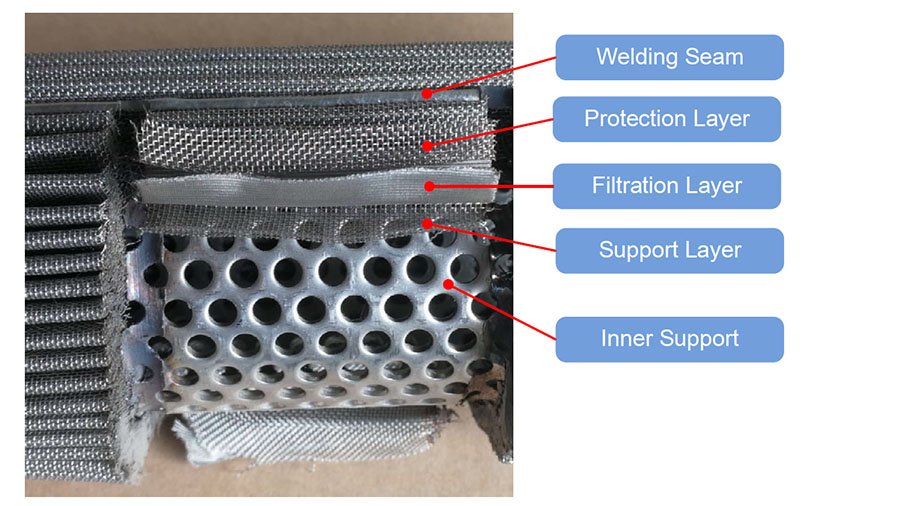

At the heart of these filters is a multi-layered sintered mesh and fiber metal felt. The pleated mesh increases the filter area, thereby extending the product’s lifespan, while the fiber metal felt provides depth filtration. The mesh adds support and rigidity, promoting finer filtration, increased dirt holding capacity, and improved permeability.

Material Options for Enhanced Performance

- The Pleated Filter Cartridge Elements, crafted from high-quality 304L or 316L stainless steel, offer robustness and versatility in filtering liquids, gases, particles, and bacteria above 0.1 um. Their welded construction enhances strength and durability, while the precision and speed of their filtration make them ideal for diverse applications demanding high filtration efficiency.

Filter Media Options

JD Hardware offers two distinct filter media options for its pleated filter cartridge elements:

- Stainless Steel Micron Woven Wire Mesh: This option typically involves two or three layers of woven wire mesh, supported internally by a perforated metal tube. An external layer of perforated metal tube is also available, depending on specific requirements. This configuration is designed to provide effective filtration while maintaining structural integrity.

- Stainless Steel Sintered Fiber/Mesh Laminate: This variant comprises multiple layers of sintered mesh media, expertly formed and welded into a cylindrical shape. The combination of multi-layer sintered mesh and fiber metal felt is pleated to enhance filtration capacity. These elements are notable for their backflushing capability, rigidity, surface filtration efficiency, and longevity across numerous cleaning cycles.

Essential Fittings and Components

- Pleated Filter Cartridge Elements from JD Hardware Wire Mesh Co., Ltd incorporate essential fittings and components to ensure versatility and ease of installation. These include threads, flanges, tie rods, and caps, each playing a crucial role in providing a secure and effective filtration setup.

Connectors for SS Pleated Filters

The SS Pleated Filters are equipped with a variety of main connector options to cater to different system requirements:

- Standard Connectors: These come in types 220, 222, and 226, offering compatibility with a wide range of filtration systems.

- Snap Coupling: This option allows for quick and easy connection, facilitating rapid assembly and disassembly.

- Thread Connection: Designed for a secure and tight fit, the thread connection is ideal for ensuring a leak-proof operation.

- Flange Connection: For systems requiring a robust and stable attachment, the flange connection offers a reliable solution.

- Rod Connection: This type of connection provides additional support and strength, especially in high-pressure environments.

- Customization: Recognizing the diverse needs of different industries, JD Hardware Wire Mesh Co., Ltd also offers custom connection options. This service allows clients to tailor their connector requirements to specific filtration systems or unique operational demands.

Characteristics

- Enhanced Filtering Area: The use of pleated mesh significantly multiplies the filtering surface, leading to longer intervals between replacements.

- Holding Capacity: These elements are designed to accommodate a high volume of dust and particles, ensuring efficient filtration over extended periods.

- Optimal Porosity and Airflow: Featuring high porosity and strong air permeability, these filters maintain low pressure, making them ideal for filtering high-viscosity media.

- Robust and Resilient Design: They are characterized by excellent strength, high-temperature tolerance, and corrosion resistance, ensuring reliability under challenging conditions.

- Reusable and Maintainable: The design facilitates easy cleaning, allowing for repeated use while maintaining high filtration standards.

- Direction of Flow: Specifically designed for water, oil, lubricants, or liquid fuels to flow from the outside to the inside of the filter element.

- Wide Micron Range: With a micron range of 5 to 840, these filter elements cater to a broad spectrum of applications, from precise filtration to basic straining.

Uses of Pleated Filter Cartridge Elements

The Pleated Filter Cartridge Elements are employed across a wide array of industries, each benefiting from their specialized filtration capabilities:

- Polymer and Synthetic Material Sector: These elements are pivotal in the manufacturing processes of synthetic fibers, plastics, and films, playing a key role in maintaining quality and purity.

- Petrochemical Applications: In the petrochemical realm, these filters are essential for processes in petrochemistry, petroleum refining, and the refinement of paints, ensuring the removal of impurities and enhancing product quality.

- Pharmaceutical and Food Industries: Their usage in pharmaceutical and food production involves synthesis, refining, and catalysis processes, as well as recycling, where purity and safety are paramount.

- Machinery and Shipbuilding: These filters are crucial in the production of hydraulic and milling oils, as well as in controlling gas flows in machinery and vessels, ensuring smooth and efficient operations.

- Air and Water Treatment: In air purification and water treatment, these elements are instrumental in sterilization and filtration processes, contributing to environmental safety and public health.

- Challenging Conditions: The filters are also uniquely suited for applications involving high temperatures, high viscosities, and high pressures, demonstrating their versatility and resilience in demanding environments.

Product Photo Showcase and Alias

Liquid Filtration Cartridges: In the context of liquid purification, they are referred to as Liquid Filtration Cartridges, adept at removing impurities from various liquids.

Industrial Air Filters: When applied in industrial air systems, they are known as Industrial Air Filters, ensuring air quality in manufacturing environments.

Oil Filtration Cartridges: In the oil industry, these elements function as Oil Filtration Cartridges, essential for purifying oils from contaminants.

Chemical Filtration Cartridges: For chemical processing, they are known as Chemical Filtration Cartridges, tailored to handle a variety of chemical filtrations.