JD Hardware Wire Mesh Co., Ltd offers a specialized range of Screen Sections, leveraging over 40 years of experience in creating diverse screening solutions. Recognized as a leading manufacturer, we provide a variety of screening services renowned for their reliability and quality.

Our extensive product line features a wide range of shaker screens for vibratory equipment, available in various hooked and edging styles to suit different industry needs. We also excel in assembling sifting screens, which include both fine and coarse mesh, along with precision-bound separator rings.

We understand the importance of versatility and customization in our field. To address this, we offer an OEM replacement service enabling customers to upgrade their old rings and frames with new, superior wire cloth. This service not only rejuvenates existing equipment but also maintains its peak performance.

JD Hardware Wire Mesh Co., Ltd is dedicated to quality, as shown in our proven processes which are vital to the expansion of our fabrication division. We engineer our screen sections to fulfill both standard and custom specifications, guaranteeing exceptional performance and enduring durability.

General Specifications and Dimensions of Screen Sections

JD Hardware Wire Mesh Co., Ltd offers a diverse range of Screen Sections, each designed to meet various industrial requirements. Here are the general specifications and dimensions:

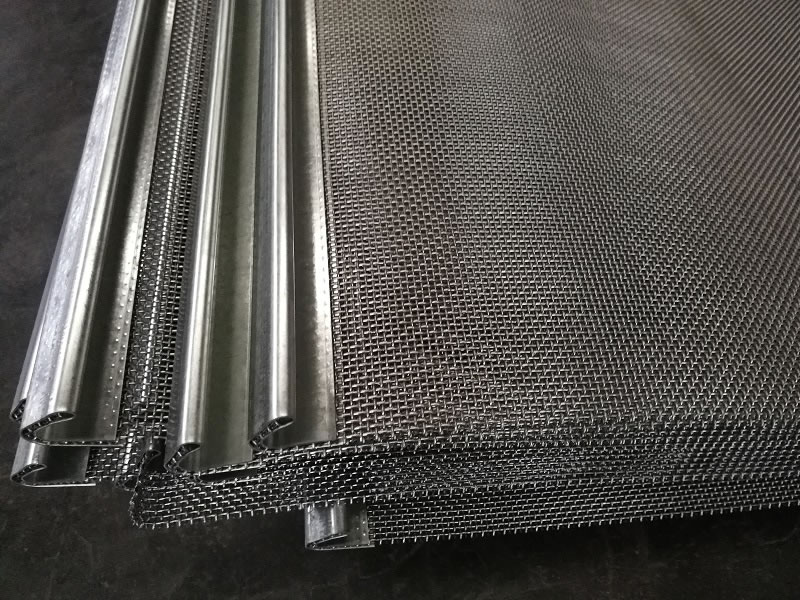

- Material Quality: Our screen sections are made from high-grade materials like stainless steel, ensuring durability and resistance to corrosion.

- Mesh Varieties: We provide a wide array of mesh options, including fine and coarse meshes, to suit different sifting and screening needs.

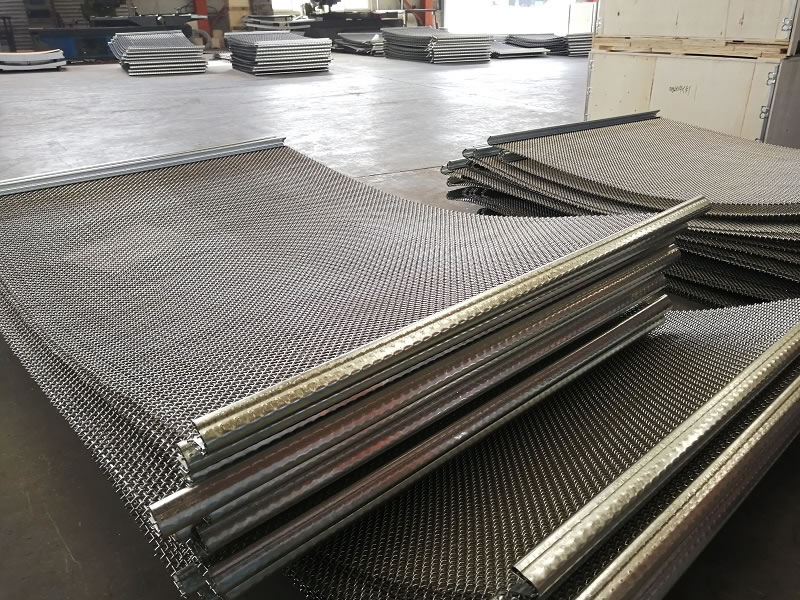

- Dimension Range: The screen sections are available in a range of sizes. Standard dimensions include small sizes (30cm x 30cm), medium sizes (60cm x 60cm), and large sizes (120cm x 120cm). Custom dimensions are also available upon request.

- Edge Styles: Our screen sections come with various edge styles, including hooked and welded, to ensure compatibility with different types of vibratory equipment.

- Frame Options: Frames for the screen sections are available in multiple designs, providing structural support and facilitating easy installation.

- Customization: We offer customization in terms of mesh type, dimensions, frame design, and edge styles to meet specific industrial requirements.

- OEM Replacement: For clients needing to replace or refurbish existing equipment, we provide OEM replacement services, allowing for the rescreening of old rings and frames with new wire mesh.

Advantages

- Innovative Edge and Frame Design: Our screen sections feature advanced edge styles and frame designs, enhancing their compatibility with a multitude of vibratory and screening equipment, and ensuring hassle-free installation.

- Resilience Against Corrosion and Abrasion: The use of corrosion-resistant and wear-resistant materials extends the lifespan of our screens, making them suitable for challenging industrial conditions.

- Optimized Screening Performance: Designed for efficiency, our screen sections contribute to improved productivity, ensuring effective separation and reduced operational downtime.

- Application Versatility: Ideal for a range of industries including pharmaceuticals, food processing, mining, and chemical manufacturing, our screens offer flexibility in application.

Product Photo Showcase and Alias

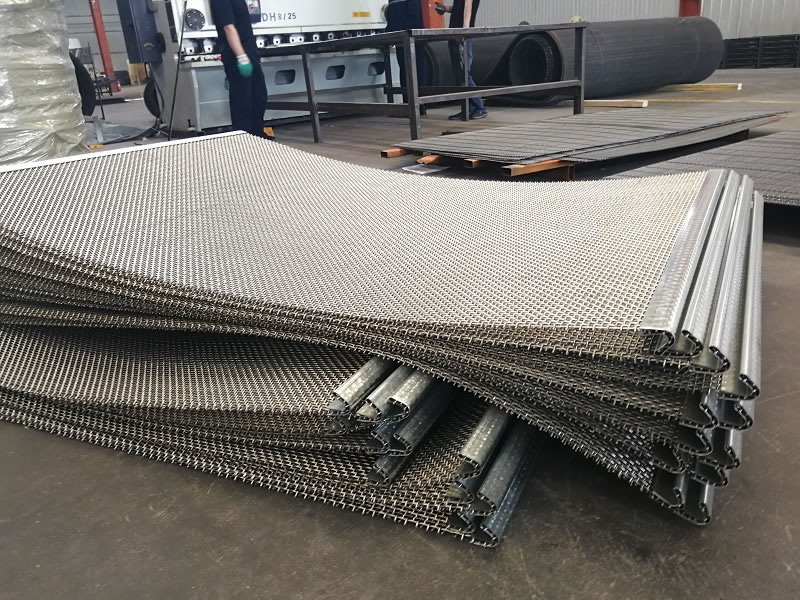

Industrial Screen Sections

Industrial Screen Sections are designed for heavy-duty applications, providing robust performance in industries like mining and construction, where durability and reliability are paramount.

Pharmaceutical Screen Sections

Pharmaceutical Screen Sections cater specifically to the pharmaceutical industry, ensuring precise and contamination-free screening essential for drug manufacturing and processing.

Food Processing Screen Sections

Food Processing Screen Sections are tailored for the food industry, offering hygienic and efficient screening solutions crucial for maintaining food safety and quality standards.

Chemical Screening Sections

Chemical Screening Sections are engineered to withstand the harsh conditions of the chemical industry, providing reliable separation and filtration of chemical substances and mixtures.

Aggregate Screen Sections

Aggregate Screen Sections are vital in construction and mining sectors for sorting and separating aggregates, ensuring consistency and quality in material grading.

Vibratory Screen Sections

Vibratory Screen Sections are optimized for use in vibratory screening equipment, enhancing efficiency and effectiveness in separating and sorting a variety of materials.