JD Hardware Wire Mesh Co., Ltd specializes in producing and exporting aluminum wire mesh products. Our aluminum wire mesh, made from this versatile metal, includes not only aluminum but also elements like copper, magnesium, manganese, and silicon, enhancing its properties. This unique composition ensures the mesh is exceptionally lightweight, approximately one-third the weight of stainless steel meshes, while maintaining strength and durability. The aluminum wire mesh we manufacture is highly resistant to corrosion in various environments, though it is vulnerable to specific alkaline solutions and acids such as hydrochloric and hydrofluoric acids. With a melting point of around 650°C, it demonstrates remarkable stability in high-temperature applications. Another key feature of our aluminum wire mesh is its cost-effectiveness, making it an economically attractive option for a wide range of industries. JD Hardware Wire Mesh Co., Ltd is dedicated to providing high-quality aluminum wire mesh solutions, designed to meet the diverse requirements of these dynamic sectors. JD, as a major supplier of aluminum woven wire mesh, primarily stocks standard grades of aluminum in alloys 5052 and 5154, which are part of the 5000 series. This series is characterized by the addition of magnesium as the main secondary element, providing hardness and excellent corrosion resistance, especially in marine environments.

Specifications and Customization

- Material Options: Our aluminum wire mesh is available in various alloys, catering to different applications. Typical alloys include A1350, A5052, A5056, and A6061, each offering unique properties suitable for specific needs.

- Wire Diameter Range: The wire diameter for our meshes varies between 0.053 mm and 0.6 mm. This range allows for flexibility in application, from fine to more robust mesh requirements.

- Mesh Count Variability: We offer a wide mesh count range from 2 to 200 MESH. This variety ensures suitability for diverse applications, from coarse to fine mesh structures.

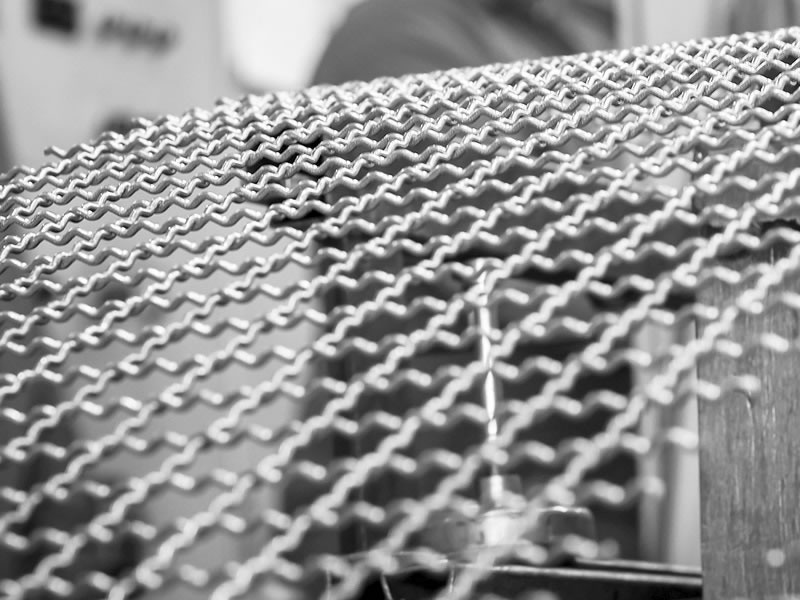

- Weave Styles: Apart from the standard plain weave, we also provide intercrimp or lock weave styles, among others, to meet specific structural and aesthetic needs.

- Dimensions: Our aluminum wire mesh is typically available in rolls of 30 meters in length. Width options include standard sizes of 1m, 1.22m, and 1.5m. Custom widths are also available to suit unique project requirements.

- Color and Surface Treatments: The standard color of our aluminum wire mesh is silver, reflecting the natural hue of the material. We offer various surface treatments such as powder coating and polishing, allowing for enhanced durability and aesthetic appeal, tailored to the client’s specifications.

- Alloys 1350 and 6061, while not standard, are available for special orders in aluminum wire mesh. These alloys may occasionally be in stock or can be manufactured upon request.

- Below is a detailed chart outlining the chemical composition limits for various aluminum wire mesh alloys:

| Alloy | Aluminum (Al) | Magnesium (Mg) | Copper (Cu) | Manganese (Mn) | Silicon (Si) | Other Elements (Total) |

| 5052 | 95.7 – 97.7% | 2.2 – 2.8% | ≤ 0.1% | ≤ 0.1% | ≤ 0.25% | ≤ 0.15% |

| 5154 | 94.2 – 96.3% | 3.1 – 3.9% | ≤ 0.1% | ≤ 0.1% | ≤ 0.25% | ≤ 0.15% |

| 1350 | ≥ 99.5% | ≤ 0.05% | ≤ 0.05% | ≤ 0.05% | ≤ 0.1% | ≤ 0.05% |

| 6061 | 95.8 – 98.6% | 0.8 – 1.2% | 0.15 – 0.4% | ≤ 0.15% | 0.4 – 0.8% | ≤ 0.15% |

Note:

The percentages represent the weight percentage of each element in the alloy.

The ‘Other Elements’ category includes trace amounts of elements that are not listed but are present in the alloy.

- Size:

| Weave Type | Mesh Count | Wire Diameter (inch) | Wire Diameter (mm) | Width of Opening (inch) | Width of Opening (mm) | % of Open Area |

| Intercrimp | 2 x 2 | 0.08 | 2.032 | 0.42 | 10.668 | 70.6 |

| Intercrimp | 2 x 2 | 0.063 | 1.6 | 0.437 | 11.1 | 76.4 |

| Intercrimp | 4 x 4 | 0.063 | 1.6 | 0.187 | 4.75 | 56 |

| Plain | 4 x 4 | 0.047 | 1.194 | 0.203 | 5.156 | 65.9 |

| Plain | 4 x 4 | 0.041 | 1.041 | 0.209 | 5.309 | 69.9 |

| Intercrimp | 5 x 5 | 0.047 | 1.194 | 0.153 | 3.886 | 58.5 |

| Plain | 5 x 5 | 0.041 | 1.041 | 0.159 | 4.039 | 63.2 |

| Plain | 6 x 6 | 0.041 | 1.041 | 0.1257 | 3.193 | 56.9 |

| Plain | 6 x 6 | 0.035 | 0.889 | 0.1317 | 3.345 | 62.4 |

| Plain | 8 x 8 | 0.041 | 1.041 | 0.084 | 2.134 | 45.2 |

| Plain | 8 x 8 | 0.032 | 0.813 | 0.093 | 2.362 | 55.4 |

| Plain | 10 x 10 | 0.025 | 0.635 | 0.075 | 1.905 | 56.3 |

| Plain | 10 x 10 | 0.02 | 0.508 | 0.08 | 2.032 | 64 |

| Plain | 12 x 12 | 0.025 | 0.635 | 0.0583 | 1.481 | 49 |

| Plain | 12 x 12 | 0.02 | 0.508 | 0.0633 | 1.608 | 57.8 |

| Plain | 14 x 14 | 0.025 | 0.635 | 0.0464 | 1.179 | 42.3 |

| Plain | 14 x 14 | 0.02 | 0.508 | 0.0514 | 1.306 | 51.8 |

| Plain | 16 x 16 | 0.02 | 0.508 | 0.0425 | 1.08 | 46.2 |

| Plain | 16 x 16 | 0.016 | 0.406 | 0.0465 | 1.181 | 55.4 |

| Plain | 18 x 18 | 0.02 | 0.508 | 0.0356 | 0.904 | 41 |

| Plain | 18 x 18 | 0.016 | 0.406 | 0.0396 | 1.006 | 50.7 |

| Plain | 20 x 20 | 0.016 | 0.406 | 0.034 | 0.864 | 46.2 |

| Plain | 20 x 20 | 0.014 | 0.356 | 0.036 | 0.914 | 51.8 |

| Plain | 24 x 24 | 0.014 | 0.356 | 0.0277 | 0.704 | 44.1 |

| Plain | 24 x 24 | 0.012 | 0.305 | 0.0297 | 0.754 | 50.7 |

| Plain | 30 x 30 | 0.012 | 0.305 | 0.0213 | 0.541 | 41 |

| Plain | 30 x 30 | 0.01 | 0.254 | 0.0233 | 0.592 | 49 |

| Plain | 40 x 40 | 0.01 | 0.254 | 0.015 | 0.381 | 36 |

| Plain | 40 x 40 | 0.008 | 0.203 | 0.017 | 0.432 | 46.2 |

| Plain | 50 x 50 | 0.008 | 0.203 | 0.012 | 0.305 | 36 |

| Plain | 60 x 60 | 0.006 | 0.152 | 0.0107 | 0.272 | 41.1 |

| Twill | 80 x 80 | 0.0055 | 0.14 | 0.007 | 0.178 | 31.4 |

| Twill | 100 x 100 | 0.0047 | 0.12 | 0.006 | 0.152 | 31.3 |

| Twill | 150 x 150 | 0.0032 | 0.081 | 0.0041 | 0.089 | 27.4 |

| Twill | 200 x 200 | 0.0022 | 0.055 | 0.0028 | 0.072 | 32.1 |

Advantages

- Lightweight: Easier handling and installation than heavier metals.

- Corrosion Resistance: Naturally resists corrosion, ideal for moist environments.

- Strength-to-Weight Ratio: Strong yet light, suitable for various applications.

- Flexibility: Easily shaped and bent for diverse uses.

- Conductivity: Good for electrical and thermal applications.

- Cost-Effectiveness: Relatively inexpensive, offering good value.

- Recyclability: Eco-friendly, fully recyclable material.

- Aesthetic Appeal: Bright, clean appearance with finishing options.

- Surface Treatment Compatibility: Can be coated or treated for enhanced properties.

Application

- Architectural and Decorative Uses: In buildings for facades, cladding, partitions, ceilings, and as decorative elements due to its aesthetic appeal and flexibility.

- Industrial Filtration: Used in filtration systems for liquids and gases because of its resistance to corrosion and high temperature.

- Security and Fencing: Lightweight yet strong, it’s used for security screens, window guards, and fencing in residential and commercial buildings.

- Pest Control: As a barrier against insects and rodents in buildings and agricultural settings.

- Automotive Industry: In car grilles and filters due to its lightweight nature and durability.

- Aerospace and Aviation: For various components where weight reduction is crucial without compromising strength.

- Electrical Applications: Used in shielding for its electrical conductivity and shielding properties.

- Marine Applications: In boats and docks for its corrosion resistance in saltwater environments.

- Food Industry: For food processing and storage given its non-toxicity and ease of cleaning.

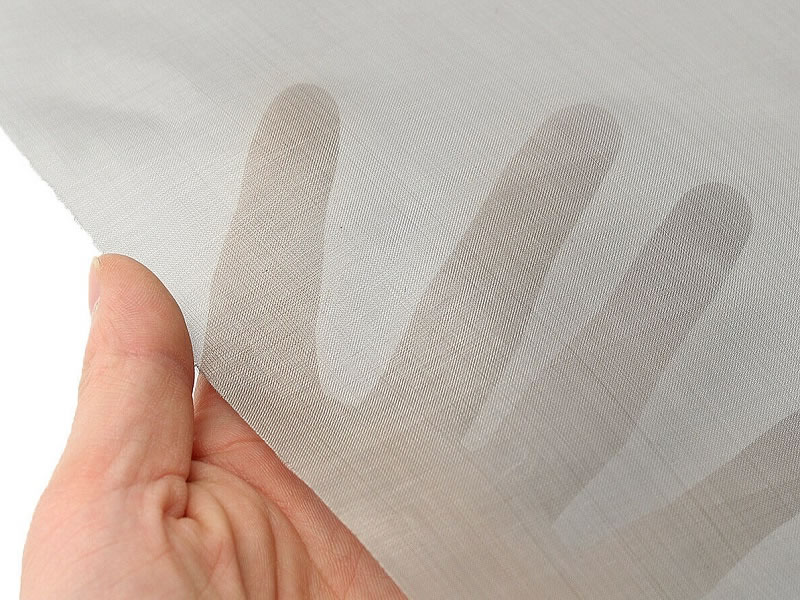

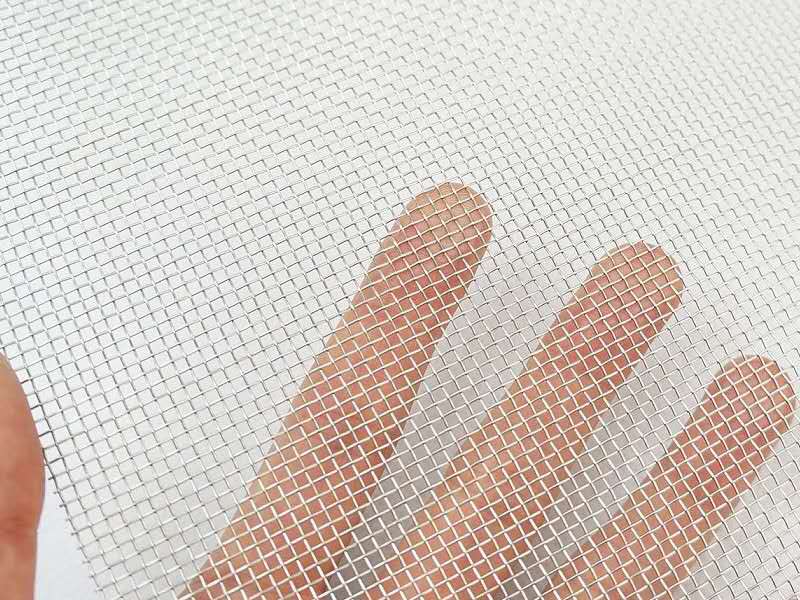

Product Photo Showcase and Alias

Aluminum Wire Fabric: Suggests a more flexible and fabric-like quality, ideal for applications requiring a combination of malleability and strength, such as in custom architectural designs or intricate industrial components.

Aluminium Woven Mesh: Focuses on the weaving aspect, indicating suitability for fine filtration systems, and in scenarios where precise mesh consistency is critical.

Aluminum Wire Netting: Often used in fencing and barrier applications, this term emphasizes its utility in creating secure yet lightweight enclosures, particularly in agricultural and residential settings.

Aluminium Mesh Sheet: Highlights its form as a flat, sheet-like material, ideal for use in cladding, paneling, and as a versatile material in various DIY and craft projects.