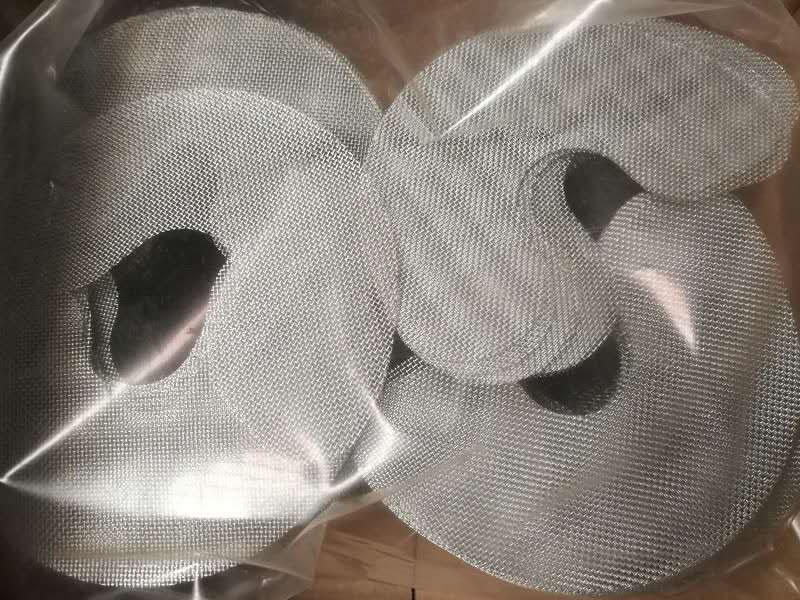

JD Hardware Wire Mesh Co., Ltd specializes in the manufacture and export of Wire Mesh Stamped Parts. Our products are crafted from single or multi-layered mesh, meticulously shaped into three-dimensional, domed structures to optimize filter area compared to traditional flat disks. We ensure the highest standards of quality through rigorous inspections, tailored to suit the scale of production and specific testing protocols. Our versatile Wire Mesh Stamped Parts are ideal for a variety of applications, including but not limited to microphone shields, noise-reduction screens, funnel screens, and filters for oil and air. They also serve as durable protective covers for various uses. With a focus on innovation and reliability, our products meet diverse industry needs, offering both functionality and efficiency.

Common Specifications and Sizes

- Standard Sizes of Wire Mesh Stamped Parts: JD Hardware Wire Mesh Co., Ltd offers a variety of standard sizes for Wire Mesh Stamped Parts, ensuring compatibility with a broad range of applications. Our products are available in diameters ranging from 30 mm to 300 mm, with depth profiles varying from 10 mm to 60 mm. These standard dimensions cater to the majority of industry needs, ensuring both versatility and convenience.

- Customization Capabilities: Understanding the diverse needs of different industries, we provide extensive customization options for our Wire Mesh Stamped Parts. Customers can request specific dimensions, with available diameter customization ranging from 20 mm to 500 mm, and depth alterations from 5 mm to 100 mm. Additionally, we offer mesh layer adjustments, allowing for single to multiple layers, tailored to the specific filtration or protective requirements of the application.

- Material Variants and Thickness Options: Our Wire Mesh Stamped Parts are available in a variety of materials including stainless steel, aluminum, and copper, catering to different environmental and durability requirements. The thickness of the mesh can also be customized, ranging from 0.5 mm to 5 mm, providing options for different levels of filtration efficiency and strength.

- Precision Engineering for Special Applications: For specialized applications, JD Hardware Wire Mesh Co., Ltd offers precision-engineered solutions. This includes exact sizing to the millimeter, tailored mesh configurations for specific filtration accuracy, and specialized shapes beyond the standard dome, such as conical, cylindrical, and custom geometric forms. This level of customization is ideal for clients requiring highly specific Wire Mesh Stamped Parts for unique applications.

Advantages of Wire Mesh Stamped Parts

- Enhanced Filtration:

Wire Mesh Stamped Parts offer superior filtration through their domed design, which provides a larger filtering area than flat alternatives. - Versatility:

These parts are suitable for various applications, including audio equipment, automotive filters, and protective covers, showing their broad usability. - Durability:

Made from materials like stainless steel and aluminum, they are durable and resistant to corrosion, ensuring long-lasting performance. - Cost-Effectiveness:

Their production, either manual or automatic, is efficient, making them a cost-effective option, especially for large orders. - Reliable Quality:

Regular quality inspections ensure high standards, guaranteeing consistent performance and reducing the likelihood of defects.

Use

- Microphone Shields: They provide protection and noise reduction for microphones, ensuring clear audio capture.

- Noise-Reduction Screens: Used in various settings to diminish environmental noise, contributing to a more controlled acoustic environment.

- Funnel Screens: Commonly used in industrial and laboratory settings, these screens assist in filtering and separating substances during pouring processes.

- Oil and Air Filters: Essential in automotive and machinery industries, they filter out contaminants from oils and air, ensuring the efficient operation of engines and machines.

- Protective Covers: They serve as protective barriers in various industrial and commercial applications, safeguarding machinery and other components from debris and other environmental factors.

Product Photo Showcase and Alias

Mesh Filter Discs: Used in filtration systems for sieving and separating particles from fluids and gases.

Acoustic Mesh Screens: Employed in audio equipment for noise reduction and sound clarity enhancement.

Noise Reduction Panels: Used in settings where sound control is crucial, helping to minimize unwanted acoustic interference.

Protective Mesh Guards: Serve as protective barriers for machinery and equipment, shielding them from environmental hazards.

Industrial Sieve Screens: Utilized in laboratories and industrial processes for material sorting and testing.

Automotive Air Filters: Installed in vehicles for protecting engine components and ensuring efficient air flow.

Liquid Filtration Meshes: Used in various industries for separating and filtering liquids.

Safety Mesh Panels: Designed to provide safety in industrial settings by guarding against mechanical hazards.

Air Distribution Meshes: Employed in systems that require controlled air flow and distribution.