JD Hardware Wire Mesh Co., Ltd provides sintered titanium filters, tailored for the rigorous demands of various industries. Crafted from premium titanium metal, these filters are distinguished by their exceptional strength and resistance to corrosion.

The sintering process compacts titanium powder under extreme temperatures and pressures, forming a filter with a porous structure and uniformly sized pores. This precision ensures consistent and effective filtration.

A key attribute of our sintered titanium filters is their significant mechanical strength, making them suitable for high-temperature and high-pressure environments. Their natural resistance to corrosion also makes them ideal for use with corrosive substances.

JD Hardware Wire Mesh Co., Ltd’s focus on quality and durability means our sintered titanium filters perform reliably in challenging settings, including chemical processing, petrochemical, pharmaceutical, and water treatment industries.

Customers opting for JD Hardware Wire Mesh Co., Ltd’s sintered titanium filters can expect a product that excels in efficiency, longevity, and quality, meeting the specific needs of their applications.

Diverse Varieties of Sintered Titanium Filters

- Sintered Titanium Mesh Filters:

Constructed by sintering multiple layers of titanium wire mesh, these filters form a porous yet strong structure. They are extensively used for filtering both gases and liquids, suitable for a range of applications due to their versatility and durability. - Sintered Titanium Powder Filters:

Produced through the sintering of fine titanium powder particles, these filters are known for their fine filtration capabilities. They are ideal for scenarios where precise filtration is critical, providing excellent corrosion resistance and mechanical strength. - Sintered Titanium Disc Filters:

These are disc-shaped filters, specifically used when a defined filtration area is necessary. Their popularity in laboratories and medical fields stems from their consistent pore size and reliable filtration performance. - Sintered Titanium Tube Filters:

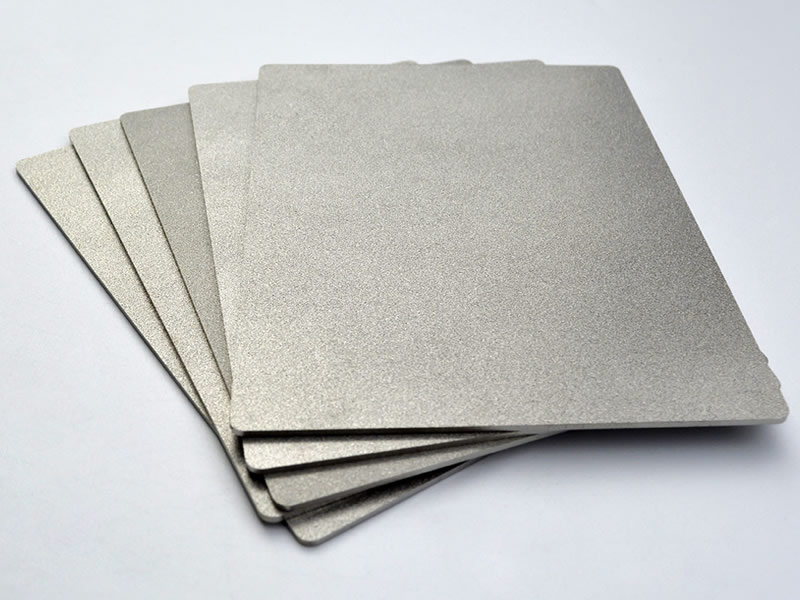

Tube-shaped for a broader filtration surface, these filters are commonly employed in the chemical industry and water treatment processes. They cater to applications requiring larger filtration areas. - Sintered Titanium Laminate Filters:

Comprising multiple layers of laminated sintered titanium, these filters boast enhanced strength and are capable of withstanding high temperatures, making them suitable for rigorous industrial applications.

Common Sizes and Customization of Sintered Titanium Filters

- Filtration Accuracy: Sintered titanium filters are available with a wide range of filtration accuracies, from ultra-fine 0.1 micrometers (μm) up to 100 micrometers (μm). This range ensures precise filtration suited for various applications, from delicate medical processes to robust industrial uses.

- Dimensions and Outer Diameter: These filters come in lengths ranging from 50mm to an extensive 1000mm, catering to different scale requirements. The outer diameters are varied, with standard sizes including Ø8mm, Ø16mm, Ø20mm, and a range from Ø30mm to Ø100mm. Such diversity in size allows for flexibility and adaptability in different system setups.

- Porosity: With a porosity range of 28-50%, these filters balance flow rate and filtration efficiency effectively. This porosity level is ideal for a variety of applications, providing optimal performance.

- Compressive Strength: The compressive strength of these filters lies between 0.5 to 1.5Mpa, indicating their ability to withstand varying degrees of pressure without compromising structural integrity.

- Temperature Resistance: These filters are designed to operate efficiently up to temperatures of ≤300 °C in wet conditions, showcasing their suitability in high-temperature environments.

- Working Pressure Difference: They are capable of operating under a working pressure difference of up to 0.6Mpa, ensuring reliable performance under various operational conditions.

- Specifications and Models: The filters are primarily available in seamless tubular forms, ensuring uniformity and strength in design.

- Interface Customization: Interface types include flat mouth, socket type (222, 226), and threaded options, with the ability to customize interfaces as per specific requirements. This customization enhances compatibility with diverse systems and setups.

Sintered Titanium Filter Precision

- Coarse to Fine Filtration Capabilities:

Sintered titanium filters are engineered to cater to diverse filtration needs, offering a broad spectrum of filter ratings. They are capable of handling coarse filtration tasks, such as filtering particles as large as 5 microns, and can also be utilized for more refined applications, reaching filtration levels at sub-micron scales. This versatility makes them suitable for various applications, from basic particulate removal to high-precision filtering.

Attributes of Sintered Titanium Filters

- Advanced Corrosion and Temperature Resistance: Sintered titanium filters excel in environments involving aggressive or corrosive substances, thanks to their superior corrosion resistance. They are also highly capable in high-temperature settings, maintaining their integrity and function in heated environments.

- Robustness and High Filtration Performance: These filters are known for their exceptional mechanical strength, a result of the sintering process, enabling them to handle high pressures and stresses. Alongside this robustness, they offer a wide range of filtration fineness, from about 5 microns to sub-micron levels, ensuring effective particle separation and consistent filtration.

- Durability and Low Maintenance: The inherent strength and corrosion resistance of titanium contribute to the filters’ durability, significantly reducing maintenance needs. This aspect, coupled with their cleanable and reusable nature, ensures a long service life and cost-effectiveness.

- Biocompatibility and Customization: Their biocompatibility makes them a safe choice for medical and pharmaceutical applications, where interaction with bodily fluids or drugs is a concern. Additionally, the ability to customize pore size and shape allows for tailored solutions to specific filtration requirements.

- Lightweight Design: Despite their strength and durability, these filters are surprisingly lightweight, an advantageous feature in applications where reducing equipment weight is crucial.

Applications of Sintered Titanium Filters

- Chemical Processing: These filters are highly effective in the filtration of aggressive chemicals and corrosive solutions, making them indispensable in the chemical processing industry.

- Oil and Gas Industry: In oil and gas sectors, they play a crucial role in filtering oil, gas, and hydrocarbons, ensuring purity and preventing contamination.

- Pharmaceuticals: Sintered titanium filters are essential for the sterile filtration of pharmaceutical products, adhering to the industry’s stringent purity standards.

- Food and Beverage Processing: They are utilized in the filtration of beverages, food products, and during brewing processes, contributing to the safety and quality of consumables.

- Aerospace Applications: In aerospace, their lightweight yet high-strength properties are vital for efficient and reliable filtration under demanding conditions.

- Water Treatment: These filters excel in water filtration, especially in environments where high temperatures or corrosive elements are present, ensuring clean and safe water.

- Petrochemical Industries: In petrochemical refining processes, these filters are used for their durability and efficiency, handling various filtration tasks effectively.

Product Photo Showcase and Alias

Sintered Titanium Chemical Filters: Engineered for the chemical industry, these filters excel in purifying aggressive chemicals and corrosive solutions, ensuring process safety and purity.

Sintered Titanium Oil & Gas Filters: In the oil and gas sector, they specialize in the filtration of hydrocarbons, playing a crucial role in maintaining the quality and safety of oil and gas products.

Sintered Titanium Pharmaceutical Filters: Designed for the pharmaceutical industry, these filters are essential for sterile filtration, ensuring the high-quality standards required for pharmaceutical products.

Sintered Titanium Food & Beverage Filters: Ideal for the food and beverage industry, they are used in filtering consumables, crucial for ensuring safety and quality in food processing and brewing.

Sintered Titanium Aerospace Filters: In aerospace applications, their lightweight and high strength make them essential for reliable filtration under demanding conditions.

Sintered Titanium Water Treatment Filters: These filters are used in water treatment, excelling in environments with high temperatures or corrosive elements, ensuring clean and safe water.

Sintered Titanium Petrochemical Filters: Utilized in petrochemical industries, they are key in refining processes, offering durability and efficiency in various filtration tasks.

Sintered Titanium High-Purity Filters: Tailored for applications requiring high levels of purity, they provide exceptional filtration efficiency and precision.

Sintered Titanium High-Temperature Filters: Specifically designed for high-temperature applications, these filters maintain performance and integrity in extreme heat conditions.

Sintered Titanium Corrosion-Resistant Filters: Optimal for environments where corrosion resistance is crucial, these filters maintain functionality and longevity in corrosive settings.