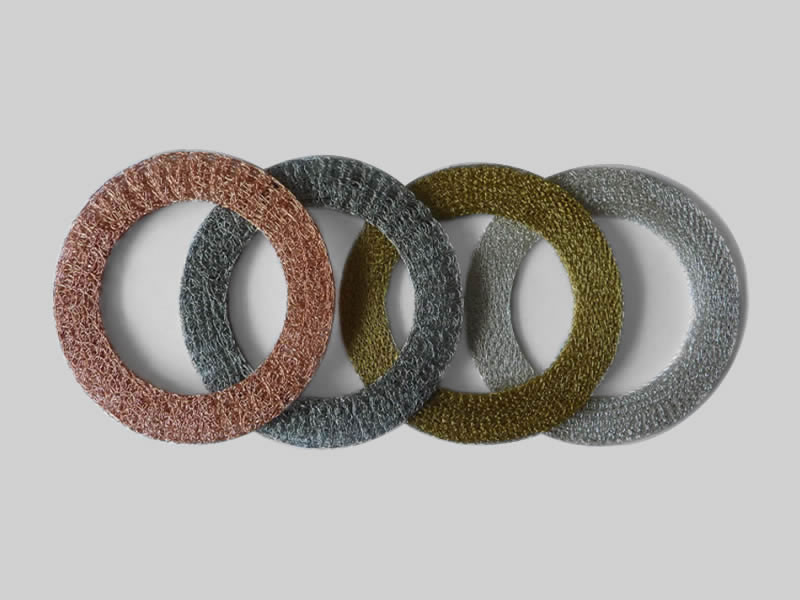

JD Hardware Wire Mesh Co., Ltd specializes in manufacturing and exporting Compressed Knitted Mesh products for diverse industrial applications. Our process involves layering, folding, and compressing knitted mesh to create various shapes such as rings, rounds, squares, and custom designs. The resulting mesh acts as a porous filter, efficiently retaining and allowing the passage of air, liquids, or oil. Our commitment lies in providing high-quality, adaptable, and reliable mesh solutions tailored to meet our clients’ specific needs.

We recognizes the diverse requirements of different industries and offers customizable compressed knitted mesh in terms of density and wire diameter. These specifications are crucial for achieving optimal filtration efficiency, dirt holding capacity, and pressure management. We balance wire size and cost to enhance both performance and affordability. Additionally, our compressed knitted mesh is notable for its vibration dampening properties, making it ideal for environments with continuous shocks, heavy loads, corrosion, or extreme temperatures. This versatility and durability make our products a favored option for a broad spectrum of applications in various sectors.

Common specifications and sizes

- Material Options:

JD Hardware Wire Mesh Co., Ltd offers Compressed Knitted Mesh in a variety of materials to suit specific industrial requirements. Our range includes stainless steel, Monel, Hastelloy, Inconel, titanium, copper, brass, tinned copper, aluminum, galvanized steel, and standard steel. Each material is selected for its unique properties, catering to different environmental and operational demands. - Wire Shape Variability:

Our Compressed Knitted Mesh is available in two primary wire shapes: round wire and flat wire. This choice allows for greater flexibility in application and performance, ensuring the mesh can be tailored to specific filtration and durability needs. - Wire Diameter Range:

We offer a comprehensive range of wire diameters, including 1mm, 0.15mm, 0.23mm, 0.25mm, 0.28mm, and 0.3mm. This variety ensures that our clients can select the optimal diameter for their specific filtration efficiency, dirt holding capacity, and pressure drop requirements. - Shape and Size Customization:

JD Hardware Wire Mesh Co., Ltd prides itself on its ability to meet clients’ specific requirements. We can shape and size the Compressed Knitted Mesh as per client specifications. This flexibility allows for the creation of mesh in various forms, including but not limited to, rings, rounds, squares, and custom-designed shapes. - Wire Number Options:

Our mesh is available in both single-wire and multi-wire structures. This range caters to different strength and flexibility needs, making our mesh adaptable to a wide range of applications, from heavy-duty industrial use to more delicate operations.

Advantages

- Precision Engineering: Our bespoke pressure molds guarantee accurately sized mesh with tight tolerances, essential for precision-dependent applications.

- Efficient Filtration with Cost-Effectiveness: Our mesh offers high filtration efficiency, serving as an economical solution for various industries.

- Rapid Production: Automated production processes enable us to reduce manufacturing time, ensuring timely delivery.

- Durability: The mesh is highly resistant to extreme temperatures and corrosion, making it ideal for challenging environments.

- Customization: We provide a range of materials, shapes, and sizes, allowing for tailored solutions to meet diverse industrial needs.

Applications of Compressed Knitted Mesh

- Oil-Gas Separation and Air Purification: Compressed knitted mesh serves effectively as a filter in oil-gas separation processes and air purification systems in various mechanical equipment. Its intricate design ensures efficient separation and purification.

- Automotive Industry: In the auto parts sector, compressed knitted mesh is used as a knitted wire muffler. It plays a crucial role in sealing, shock absorption, sound reduction, and exhaust purification, enhancing the overall functionality and efficiency of automotive parts.

- Electronics and Electrical Appliances: This mesh also finds applications in the electronics and electrical appliance industries, where it is used as a shielding device. Its properties help in protecting sensitive components from external interference, ensuring device integrity and performance.