JD Hardware Wire Mesh Co., Ltd specializes in the manufacturing and export of filter discs, also known as wire mesh discs. Our products, crafted from high-quality materials such as stainless steel woven mesh, stainless steel sintered mesh, galvanized wire mesh, and brass wire cloth, are designed to efficiently remove impurities from fluids, air, or solids. The versatility of our filter discs is evident in their design options – available as single or multi-layer filter bags with either spot-welded or aluminum-framed edges. Our range of shapes includes circular, square, polygonal, and oval, catering to diverse industry needs. Some of our filter discs also feature multi-layered construction achieved through spot welding, enhancing their filtering capability. These features make our products indispensable in various sectors, including petroleum, chemical, metallurgy, food and beverage, medical, and automotive industries. JD Hardware Wire Mesh Co., Ltd is committed to providing solutions that meet the critical absorption, evaporation, and filtration needs of our customers, ensuring quality and reliability in every product.

Filter Disc Specifications and Customization

- Material Selection: JD Hardware Wire Mesh Co., Ltd offers a diverse range of materials for filter discs. The selection includes robust Stainless steel wire, ideal for high-strength requirements; Stainless steel sintered for enhanced filtration efficiency; Brass wire, known for its corrosion resistance; Phosphor copper wire mesh, offering superior flexibility; Nickel Wire Mesh, favored for its thermal and electrical conductivity; Monel Mesh, recognized for its excellent corrosion resistance in marine environments; and Inconel Mesh, sought after for its ability to withstand extreme temperatures. This variety ensures that each filter disc can be tailored to the specific environmental and operational needs of our clients.

- Shapes and Sizes: Our filter discs come in multiple shapes and sizes: Round shapes range from a compact diameter of 44mm, suitable for smaller applications, up to a substantial 600mm for larger scale operations. Ring-shaped discs offer inner diameters from 18mm to a generous 250mm, with outer diameters stretching from 50mm to 350mm, catering to a broad spectrum of industrial needs. Rectangular shapes are available in widths from 50mm to 100mm and lengths from 60mm to 400mm, providing versatility for different filtering environments. These precise dimensions ensure optimal fit and functionality in various applications.

- Thickness and Mesh Size: Thickness options range from 0.1mm to 6mm, and mesh sizes are available from 10 mesh to 635 mesh. These variations allow for tailored filtration capabilities, from coarse to fine, depending on the specific requirements of the application.This extensive range in thickness and mesh size allows for exceptional customization, ensuring that each filter disc is perfectly suited to its intended application, whether it requires coarse or fine filtration.

- Structure and Techniques: We offer Single, Double, and Multi-layer structures, with or without frames, and with options for spot-welded or non-spot-welded construction. Single Layer structures offer simplicity and cost-effectiveness, Double Layer structures provide added strength and durability, and Multi-layers offer superior filtration capabilities. These choices provide different levels of strength and filtration efficiency, catering to various industrial demands.

- Customization: Understanding that every industry has unique requirements, JD Hardware Wire Mesh Co., Ltd provides bespoke customization for filter discs. Clients can specify their exact needs in terms of material, shape, size, thickness, mesh size, structure, and fabrication technique. This level of customization ensures that each filter disc is precisely engineered to provide optimal performance in its specific application, whether in standard industrial processes or in specialized environments.

Filter Disc Advantages

- Precision Manufacturing: Using advanced technology for a firm weave and regular mesh, ensuring reliable filtration.

- Robust Performance: Resistant to friction, corrosion, and high temperatures, suitable for tough environments.

- Efficient Filtration: Designed to effectively remove impurities from liquids or gases, ensuring process purity.

- Easy Maintenance: Designed for straightforward cleaning, enhancing longevity and consistent performance.

- Cost-Effective: Offers an economical filtration solution, especially with reusable materials.

- Precision in Filtration: Capable of removing very fine particles, ideal for high-precision applications.

Filter Disc Features

- Diverse Micron Ratings: Filter discs come with various micron ratings, allowing for precise filtration suited to specific needs, ensuring optimal particle capture.

- Superior Filtration Quality: Boasting smooth surfaces and fine meshes, these discs guarantee exceptional filtration performance by effectively trapping even the smallest particles.

- Multi-Layer Construction: Available in multiple layers, these discs provide enhanced mechanical strength coupled with fine filtration capabilities, ideal for more demanding applications.

- No Media Migration: Expertly designed to prevent the migration of filtering media, ensuring consistent and reliable filtration without contamination.

- Cost-Efficient: Designed to offer a low-cost solution to filtration needs, making them a budget-friendly choice for many industries.

- Maximum Protection: Engineered to provide maximum protection against impurities, thereby safeguarding the integrity of the filtering process and the end product.

- Minimal Pressure Drop: These discs are designed to minimize pressure drop across the filter, ensuring efficient operation and reduced energy consumption.

- Reusability: Capable of being rinsed and reused repeatedly, these filter discs are not only economical but also environmentally friendly, reducing waste and operational costs.

Filter Disc Applications

- Chemical Industry: Used for purifying chemicals and protecting equipment from particulates.

- Pharmaceutical Production: Essential in filtering process fluids to ensure medication purity.

- Food and Beverage: Helps in clarifying liquids and oils, maintaining health standards.

- Water Treatment: Filters contaminants from drinking and wastewater, supporting environmental health.

- Petrochemical Processes: Removes impurities from oils and fuels, enhancing product quality.

- Automotive Filtration: Used in vehicles for oil, fuel, and air filtration, crucial for performance.

- Aerospace and Defense: Filters fluids in sensitive aerospace and defense systems.

- Electronics Manufacturing: Ensures air and liquid cleanliness in semiconductor production.

- Laboratory Research: Provides accurate, contamination-free results in research settings.

Product Photo Showcase and Alias

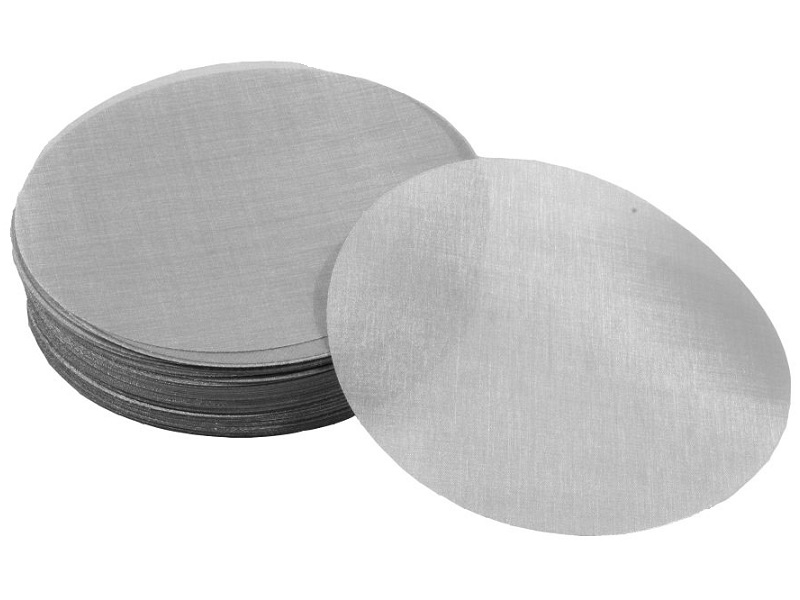

Filtration Disc:

Ideal for precise separation processes, this disc is utilized in applications requiring high-level filtration accuracy.

Mesh Filter Disc:

Commonly employed in chemical and pharmaceutical industries, it effectively filters out minute particles, ensuring product integrity.

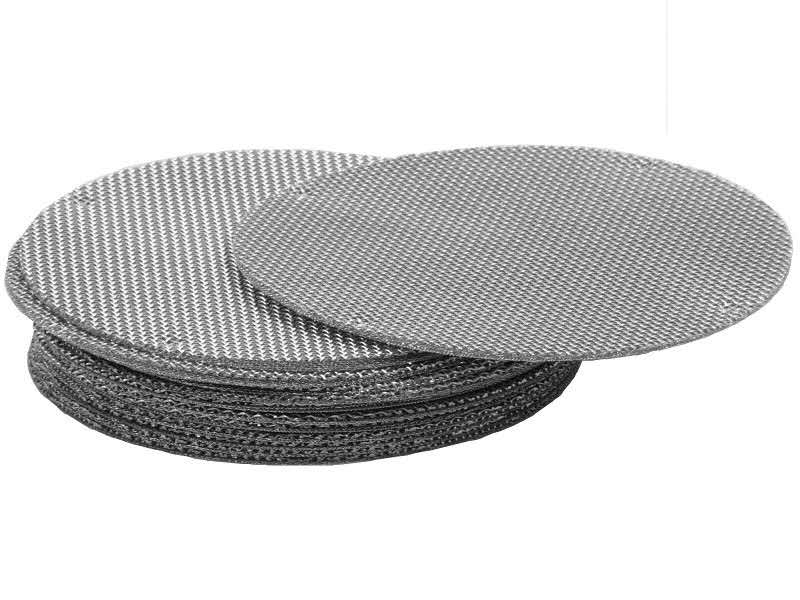

Screen Filter Disc:

This variant is crucial in water treatment and food processing, where it separates solids from liquids while maintaining flow efficiency.

Wire Mesh Filter Disc:

Often used in petroleum and automotive industries, it’s designed to withstand high pressure and harsh conditions while filtering impurities.