JD Hardware Wire Mesh Co., Ltd provides Temporary Basket Strainers, ideal for coarse filtration in pipeline systems. Known for their versatility as flat top conical, truncated mesh line, and hat type strainers, they play a vital role in removing large solid particles from fluids. This function is key to ensuring the smooth operation of critical machinery and equipment like compressors and pumps, thereby aiding in continuous and safe production.

Featuring a mesh screen, these strainers effectively separate impurities, ensuring only clean fluid passes through. A notable feature is their maintenance-friendly design; the removable cartridge is easily taken out, cleaned, and reinstalled, streamlining maintenance and reducing downtime.

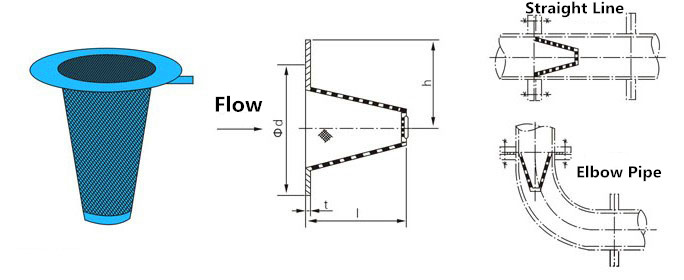

Designed for installation in equipment pipelines before operations start, they are placed between two flanges for efficient debris filtration. Their easy installation and dependable performance make them a top choice in various industrial settings. Their simple yet robust design has made them widely popular in sectors where fluid cleanliness is essential.

Common Sizes and Customization Capabilities

JD Hardware Wire Mesh Co., Ltd provides a wide array of Temporary Basket Strainers, tailored to meet diverse industrial requirements with an extensive range of specifications and custom options. Each option is meticulously crafted, balancing durability, efficiency, and compatibility, to ensure our strainers fulfill the varied and precise needs of different industrial sectors.

- Material Options: Our Temporary Basket Strainers are available in a range of materials to suit different applications, including Stainless Steel grades 304, 304L, 316, and 316L, as well as Monel and other alloys upon request. This variety ensures compatibility with various fluid types and environments, from general water handling to more corrosive or high-temperature applications.

- Shape and Type Variability: We provide strainers in several shapes and types, including flat bottom cone strainers, cylindrical pipeline strainers with flanges, and other customized shapes to meet specific requirements. This flexibility allows for precise fitting and functionality in different pipeline systems.

- Filter Media Customization: Our strainers come with multiple filter media options. Customers can choose from strainers with only a perforated metal structure, only a woven wire mesh structure, or combinations of both. Options include outside perforated metal with inside woven mesh, outside woven wire mesh with inside perforated metal, and strainers with internal wire support and external woven wire mesh. This versatility ensures optimal filtration based on the nature of the impurities and the required filtration grade.

- Layer Options: To accommodate varying filtration needs, our strainers are available in different layer configurations. Options include a single layer of perforated metal mesh without inner wire cloth, a single layer of wire cloth, or multiple layers of wire cloth. These choices allow for customization in terms of filtration efficiency and particle size retention, ensuring that each strainer meets the specific needs of its application.

Features

- High Filtration Accuracy:

These strainers boast an impressive removal rate of over 95% for suspended solids in water. They are highly effective in filtering out macro molecules, organic matter, viruses, bacteria, colloids, iron, and other impurities, offering superior purification. - Exceptional Filtration Speed:

The filtration speed of these strainers is generally around 40m/h, with a peak capability of up to 60m/h. This rate is three times faster than that of ordinary sand filters, making them significantly more efficient. - Increased Pollutant Handling:

Our strainers can handle approximately 15 to 35kg/m3 of pollutants, which is four times the capacity of traditional sand filters. This feature allows for more extensive filtration before requiring maintenance. - Compact Design:

Compared to ordinary sand filters, these strainers require 1/3 less space to filter the same amount of water. This compact design makes them ideal for applications where space is at a premium. - High Adjustability:

The filtration accuracy, interception capacity, filtration resistance, and other parameters of these strainers are fully adjustable to meet specific requirements. This adaptability ensures optimal performance in a variety of filtration tasks.

Temporary Basket Strainers Usage

- Chemical and Petrochemical: Ideal for filtering weak corrosive materials like water, ammonia, oil, and hydrocarbons.

- Corrosive Chemicals: Crucial in filtering strong acids and chemicals, including caustic soda and sulfuric acid, in chemical manufacturing.

- Refrigeration: Suitable for low-temperature substances like liquid methane and ammonia in refrigeration systems.

- Food and Pharma: Used in processing consumables and pharmaceuticals, ensuring health standards are met in products like beer and dairy.

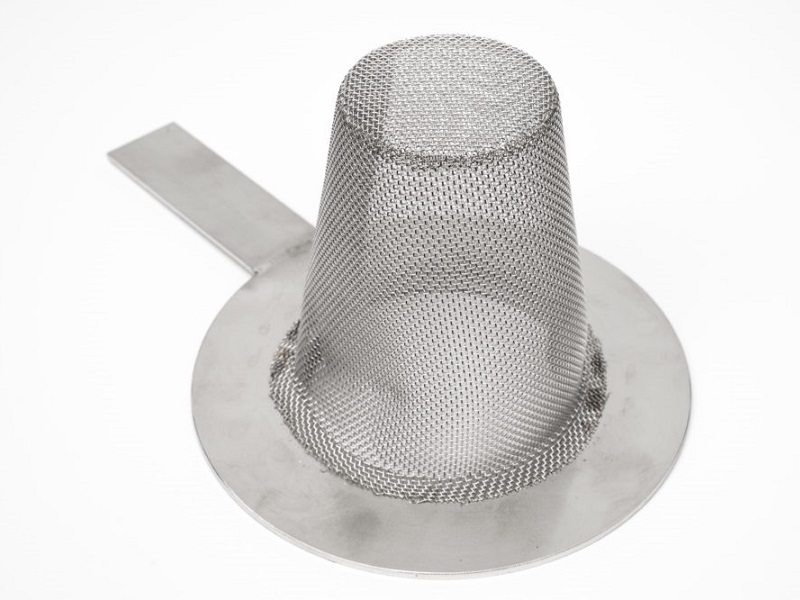

Product Photo Showcase and Alias

Cone Type Strainers: Shaped like a cone, these are designed for quick and easy installation, ideal for short-term use in various industries.

Basket Type Strainers: Featuring a basket-like design, these strainers offer a larger surface area for filtration, suitable for more extensive temporary filtration needs.

Flat Type Strainers: With a flat-shaped design, these are used in systems where space constraints are a consideration, providing effective filtration without requiring much

Temporary Cone Strainer: Ideal for short-term filtration needs, commonly used in pipe start-up processes to remove debris.

Pipeline Debris Catcher: Used in pipelines to trap and remove solid particles during system maintenance or installation.

Start-Up Strainer Basket: Employed at the beginning of operations to ensure clean and contaminant-free system start-ups.

Interim Fluid Filter: Acts as a provisional solution for filtering fluids in various industrial applications during transitional phases.

Temporary Inline Strainer: Designed for inline installation, it provides immediate filtration in existing pipeline systems.

Short-Term Sediment Strainer: Captures sediments temporarily in various liquid processes, especially during system tests or changes.

Removable Mesh Basket: A detachable strainer for flexible use in different stages of fluid processing or system operation.

Process Start Strainer: Facilitates the initial phase of various industrial processes by filtering out unwanted particles from fluids.