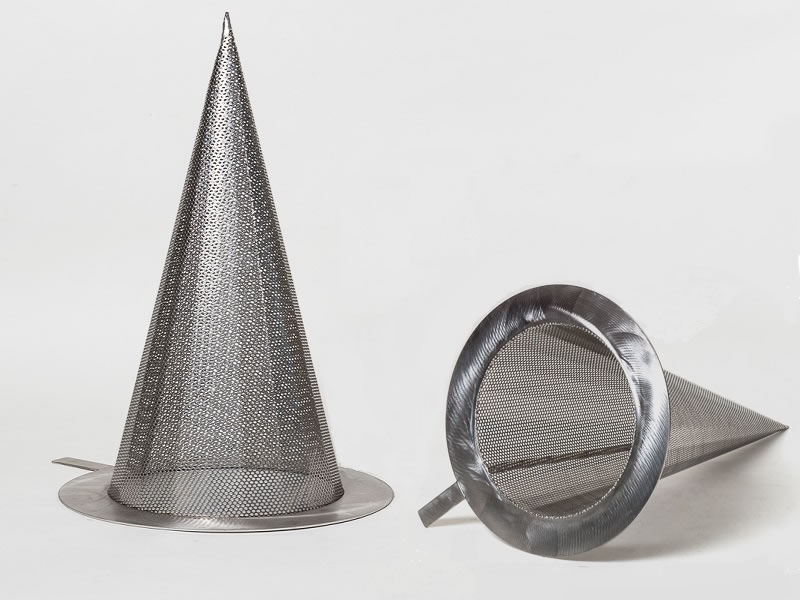

JD Hardware Wire Mesh Co., Ltd specializes in the manufacture of Stainless Steel Cone Filter Screens, expertly engineered to meet a diverse range of filtration needs. Our Cone Filter Screens, shaped distinctly in a cone, are crafted from high-quality stainless steel mesh. This unique design enhances filtration efficiency by effectively channeling material flow and facilitating superior particle separation.

Ideal for industrial, commercial, and residential settings, these filters excel in various applications. Whether it’s for liquid-solid separation or for purging gases of particulate matter, our screens offer unparalleled performance. The robust construction of stainless steel not only ensures longevity but also provides resistance against corrosion and high temperatures, making them suitable for a multitude of environments.

Our commitment lies in delivering products that embody precision and quality. The Stainless Steel Cone Filter Screens from JD Hardware Wire Mesh Co., Ltd are not just tools but solutions designed to elevate the efficacy of your filtration processes.

Common Specifications and Standard Sizes

- Materials: Our range includes a variety of materials such as Stainless Steel 304, 316, 316L, Monel, and Galvanized Materials. Each material is carefully selected to suit different environmental conditions and specific applications, ensuring optimal performance and durability.

- Mesh Type: We provide a selection of mesh types including Perforated Metal, Sintered Mesh, Woven Mesh, and Photo Etched Metal. These options allow for precise control over filtration accuracy, catering to a wide range of industrial requirements and ensuring superior filtration quality.

- Mesh Size Customization: Our services include the customization of mesh sizes to target specific particle sizes, thereby achieving precise filtration for specialized applications. This tailored approach ensures that our filters meet the exact needs of each unique application.

- Filter Types: In addition to cone filters, we specialize in customizing a variety of filter types such as Filter Baskets, Tubes, Washers, and Filter Discs. This extensive range provides comprehensive filtration solutions, adaptable to various industrial processes and requirements.

- Tailor-Made Designs: We excel in creating tailor-made filter designs based on detailed client drawings and samples. This personalized service guarantees that each filter is crafted to meet specific requirements, ensuring a perfect fit and optimal functionality for our clients’ unique needs.

- Standard Sizes: Our Stainless Steel Cone Filter Screens are available in standard sizes to accommodate diverse industrial applications. Small sizes range from 2 to 4 inches in diameter for precision tasks in smaller systems. Medium sizes span 5 to 10 inches, ideal for moderate-scale operations. Large sizes, extending from 11 to 20 inches in diameter, are designed for large-scale industrial processes, ensuring efficiency and effectiveness across a spectrum of uses.

Advantages

- High Filtration Efficiency: The conical shape enhances the filtration process by effectively channeling the flow of materials, which leads to better particle separation and a more thorough filtration.

- Durability: Made from high-quality materials like stainless steel, these filters are highly durable. They resist corrosion, withstand high temperatures, and are suitable for harsh industrial environments, ensuring a long service life.

- Versatility: The availability of different materials (Stainless Steel 304, 316, 316L, Monel, etc.) and mesh types (Perforated Metal, Sintered Mesh, Woven Mesh, Photo Etched Metal) makes these filters adaptable to various applications, ranging from industrial to residential.

- Wide Range of Applications: Due to their design and material properties, Cone Filter Screens are suitable for a wide range of applications, including chemical processing, food and beverage production, pharmaceuticals, water treatment, and oil and gas industries.

- Ease of Maintenance and Cleaning: These filters are designed for easy cleaning and maintenance, which is essential for maintaining optimal filtration performance and extending the filter’s lifespan.

- Effective Solid-Liquid Separation: Cone Filter Screens are particularly effective in separating solids from liquids, making them ideal for applications in wastewater treatment, food processing, and chemical industries.

- Cost-Effective: Despite their high quality and efficiency, Cone Filter Screens are a cost-effective solution. Their durability and long lifespan mean fewer replacements and lower maintenance costs over time.

Applications

- Chemical Processing: For filtering impurities in chemical production.

- Food and Beverage: Essential in purifying liquids like oils and syrups.

- Pharmaceuticals: Used in the purification of drugs, where high precision is crucial.

- Water Treatment: In both industrial and municipal settings for sediment and contaminant removal.

- Oil and Gas: For filtering in oil and gas production processes.

- Automotive Industry: In filtering automotive oils and fluids.

- Aerospace and Defense: For fuel and hydraulic system filtration.

- Agriculture and Irrigation: In water filtration for irrigation systems.

- Mining and Mineral Processing: For mineral separation and water treatment in mining.

- Petrochemicals: In refining and processing, removing impurities from products.

Product Photo Showcase and Alias

Industrial Cone Filter: In industrial settings, this filter plays a crucial role in removing large particulates from liquids, vital for maintaining machinery and product purity.

Cone Water Filter: Designed for water treatment, it effectively removes contaminants and sediments, ensuring clean and safe water for various uses.

Cone Oil Filter: Essential in the automotive and manufacturing sectors, this filter is adept at purifying oils, crucial for machinery performance and longevity.

Chemical Cone Filter: In the chemical industry, this filter is key for separating fine particulates from chemical solutions, ensuring product quality and safety.

Pharmaceutical Cone Filter: In pharmaceutical manufacturing, it’s used for the precise filtration of medicinal solutions, critical for product efficacy and safety.

Cone Mesh Filter: Known for its fine mesh design, it’s used in applications requiring precise filtration, such as in laboratory settings and fine chemical processing.