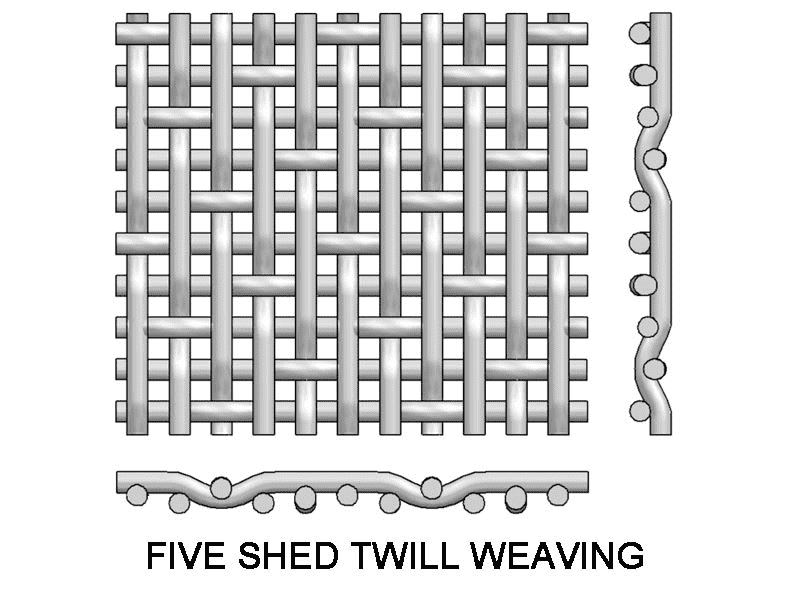

JD Hardware Wire Mesh Co., Ltd is committed to providing products that cater to the unique needs of our customers across various filtration applications. Our Five-Heddle Weave Wire Mesh is a prime example of this commitment, embodying both quality and functionality. Specializing in the manufacture of this mesh, we focus on a design that is both efficient and stable.

The distinctive weaving pattern of our Five-Heddle Weave Wire Mesh involves each warp wire intricately interlacing under and over combinations of one and four weft wires, and in a different sequence, two and three weft wires. This specialized method results in a mesh that is both detailed and well-balanced. Its open mesh structure enables high flow rates while maintaining robust mechanical stability.

A key feature of our Five-Heddle Weave Wire Mesh is its smooth surface, which greatly facilitates the removal of filter cake and simplifies the cleaning process. This characteristic renders the mesh particularly advantageous for use in drum and disc filter equipment. In such applications, it excels in managing continuous cycles of filter cake build-up, removal, and maintenance, showcasing its exceptional performance and reliability.

Specifications and Customization

Material Options:

Standard Stainless Steels

- 304, 304L, 316, 316L, 321: These grades offer a balance of corrosion resistance and strength, suitable for a variety of standard applications.

Specialized Stainless Steels and Nickel-Based Alloys:

- 310/314, 904L: Ideal for high-temperature environments, offering excellent resistance to oxidation and corrosion.

- Alloy 400, 600, 601, 625, 800, 825: Designed for use in harsh chemical environments, providing exceptional chemical resistance.

- Alloy C22, C276, Alloy DS: Known for their superior corrosion resistance, these alloys are optimal for chemical processing industries.

- Feral: A choice for applications requiring high strength and durability.

Nickel & Non-Ferrous Metals:

- Nickel, High-Grade Nickel: Best suited for conditions requiring robust performance, including extreme environments.

- Bronze, Brass, Copper: Offer unique properties such as resistance to biofouling and electrical conductivity, making them suitable for specialized applications.

Weaving Type:

- 5-Heddle Weave: This weaving style provides a perfect balance of filtration efficiency and structural strength, ideal for diverse filtering applications.

Standard Widths:

- Range from 0.15m to 1.6m:

Smaller widths: Ideal for detailed and precision-based applications.

Larger widths: Suitable for applications requiring broader coverage and larger-scale filtering.

Standard Roll Lengths:

- 30m, 100′, 200′, 300′:

- 30m rolls: Commonly used for standard industry applications.

- Extended lengths (100′, 200′, 300′): These lengths cater to larger projects or continuous use in industrial settings.

Customization Capabilities:

- Each aspect of our Five-Heddle Weave Stainless Steel Wire Mesh can be tailored to specific needs. Whether it’s adjusting the material for specific environmental conditions, customizing the width for unique application requirements, or altering the roll length for large-scale projects, our customization services ensure that the mesh meets the exact specifications of our clients. This adaptability makes our mesh a versatile choice for industries ranging from filtration and chemical processing to aerospace and construction.

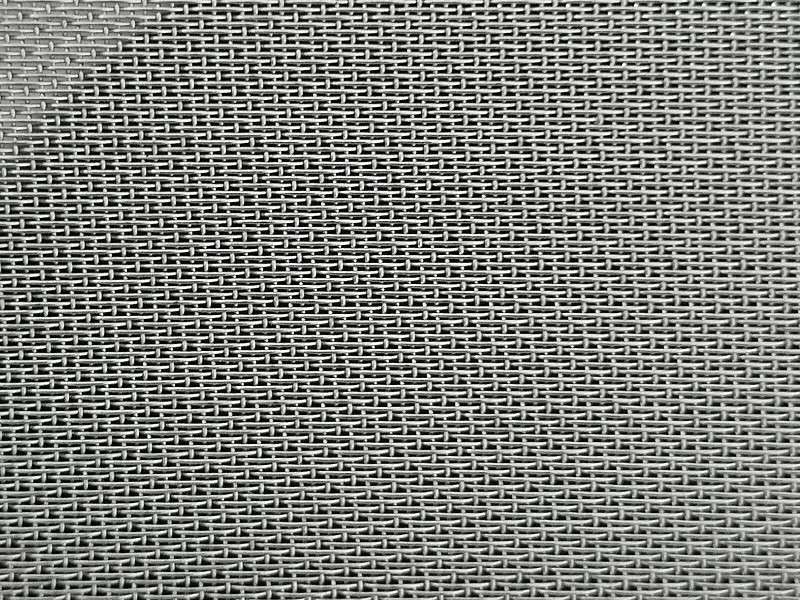

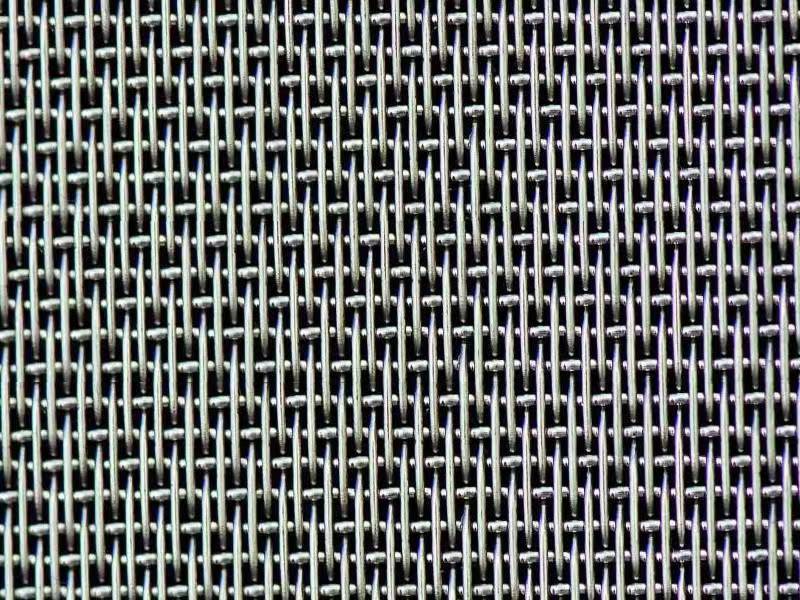

Product Photo Showcase and Alias

Five-Heddle Weave Industrial Filtration Mesh: Primarily used in industrial filtration systems, this mesh is designed for environments where durability and high flow rates are critical, making it perfect for heavy-duty industrial filtering.

Five-Heddle Weave Chemical-Resistant Mesh: Employed extensively in the chemical sector, this mesh is chosen for its ability to resist corrosive substances, ensuring longevity and reliability in chemical filtration applications.

Five-Heddle Weave High-Flow Drainage Mesh: Ideal for drainage systems requiring efficient liquid flow, this mesh facilitates rapid water passage while effectively trapping sediments, enhancing drainage efficiency.

Five-Heddle Weave Paper Production Mesh: In the paper-making industry, this mesh is utilized for its strength and durability, playing a crucial role in the dehydration process of paper pulp.

Five-Heddle Weave Process Filtration Mesh: Adapted for various process filtration needs, from water to air purification, this mesh ensures high efficiency and versatility in different filtration scenarios.

Five Heddle Weave Wire Cloth Customized Specifications Table

| Meshes per inch | Wire Diameter (mm) | Micro Retention | Thickness | Approx.Weight | |||

| Warp count | Weft count | Warp wire | Weft wire | abs. μm | nom. Μm | mm | Kg/m2 |

| 30 | 18 | 0.5 | 0.5 | 0.60-0.65 | 0.37 | 1.48 | 3 |

| 28 | 17 | 0.47 | 0.47 | 0.75-0.80 | 0.46 | 1.41 | 2.53 |

| 24 | 20 | 0.6 | 0.6 | 0.65-0.75 | 0.49 | 1.7 | 3.96 |

| 15 | 13 | 0.9 | 0.9 | 1.15-1.20 | 0.85 | 2.6 | 5.67 |

| 80 | 60 | 0.2 | 0.2 | 0.20-0.22 | 0.127 | 0.55 | 1.4 |

| 77 | 40 | 0.24 | 0.24 | 0.38-0.40 | 0.095 | 0.68 | 1.65 |

| 65 | 36 | 0.3 | 0.3 | 0.26-0.29 | 0.1 | 0.84 | 2.27 |

| 55 | 36 | 0.3 | 0.3 | 0.25-0.28 | 0.175 | 0.84 | 2.05 |

| 132 | 85 | 0.14 | 0.2 | 0.09-0.11 | 0.052 | 0.44 | 1.47 |

| 107 | 132 | 0.16 | 0.14 | 0.055-0.065 | 0.055 | 0.44 | 1.3 |

| 107 | 125 | 0.16 | 0.14 | 0.065-0.08 | 0.07 | 0.45 | 1.27 |

| 107 | 59 | 0.16 | 0.16 | 0.16-0.18 | 0.077 | 0.45 | 1.09 |

Features

- Strength: Compared to common types of metal wire meshes, the Five-Heddle Weave Wire Mesh exhibits superior strength. This enhanced durability is due to its unique weave pattern and the quality of materials used in its construction.

- High Flow Rates: This type of wire mesh is designed to facilitate high flow rates. The specific weave pattern allows for efficient passage of liquids and gases, making it ideal for various filtration processes.

- Ease of Cleaning: The structure of the Five-Heddle Weave Wire Mesh allows for easy maintenance and cleaning. Its design minimizes the accumulation of particles, and its smooth surface can be conveniently cleaned to maintain optimal performance.

Application

- Drainage Filtration: The mesh is extensively used in drainage systems where efficient and reliable filtration is required. Its high strength and flow rate capabilities make it an ideal choice for this application.

- Undercurrent Filtration: In undercurrent filtration systems, the Five-Heddle Weave Wire Mesh is utilized due to its ability to handle high flow rates and its effectiveness in filtering out contaminants.

- Dehydration in Paper-Making: The mesh is also suitable for dehydration processes in the paper-making industry. Its strength and durability can withstand the demanding conditions of paper production.

- Chemical Fillers: In the chemical industry, this wire mesh is used as a filler material due to its chemical resistance and structural integrity. Its properties ensure efficient operation in harsh chemical environments.