JD Hardware Wire Mesh Co., Ltd specializes in producing and exporting high-quality knitted mesh filters for various industrial applications. Our filters are designed for efficient filtration in sectors like cooking, chemicals, and petroleum, ensuring thorough oil and gas purification. Characterized by their large surface area, these filters provide superior performance with low resistance and boast a filtering efficiency of up to 98%, distinguishing them from other types in the market. Understanding the importance of precise filtration, JD Hardware Wire Mesh Co., Ltd offers a wide range of knitted mesh filters, customizable to meet specific industry needs and preferences.

One of the primary applications of our filters is in the realm of grease filtration. These filters are strategically installed above cooking areas to effectively trap grease and fat, thereby mitigating the risk of fire in extraction systems and safeguarding essential components like motors and blowers.

Our Product Range Includes:

- Wire Type Variants: We offer filters made from both round and flat wire knitted mesh, giving clients the flexibility to choose based on specific requirements.

- Material Options: Our portfolio extends to filters made from both metal and plastic wires, allowing for a broad spectrum of applications and environments.

- Supporting Grilles Selection: Catering to various structural needs, our filters come with options of welded, crimped, or expanded metal mesh grilles.

Knitted Mesh Filter Specifications

- Materials:

Knitted Mesh Filters are available in a variety of materials to suit different environments and applications. Options include stainless steel wire, aluminum wire, copper wire, Monel wire, titanium wire, and polypropylene wire. Each material offers unique properties, such as corrosion resistance, strength, and flexibility, making them suitable for a range of industrial uses. - Wire Types:

Customers can choose between flat wire and round wire types for their knitted mesh filters. The selection depends on the specific application requirements, such as the desired flexibility, strength, and filtration efficiency. - Wire Diameter

Round Wire: Available in diameters ranging from 0.08 mm to 0.5 mm, allowing for precise customization based on the required filtration fineness and strength.

Flat Wire: Offered in dimensions including 0.1 mm × 0.3 mm, 0.1 mm × 0.4 mm, 0.2 mm × 0.4 mm, and 0.2 mm × 0.5 mm. These dimensions provide versatility in filter construction, catering to various levels of rigidity and filtration capabilities. - Mesh Openings:

Mesh opening sizes for knitted mesh filters vary from 2 mm × 3 mm to 12 mm × 6 mm. This range ensures that filters can be tailored for different levels of filtration, accommodating everything from fine to coarse separation requirements.

Advantages

- Exceptional Filtration Efficiency: With up to 98% efficiency, knitted mesh filters are highly effective in trapping and removing particles from gases and liquids, providing superior purification.

- Customizable Design: The ability to choose from various materials, wire types, diameters, and mesh openings allows for tailored solutions to meet specific filtration needs and environmental conditions.

- Durability and Longevity: Made from robust materials like stainless steel and titanium, these filters are designed to withstand harsh conditions, reducing the need for frequent replacements and ensuring long-term reliability.

- Low Pressure Drop: Despite their high filtration capacity, these filters maintain a low resistance to flow, minimizing the impact on system pressure and enhancing overall efficiency.

- Versatile Application: Suitable for a broad range of industries, including petroleum, chemical, and food processing, they can be used in various environments from high-temperature industrial processes to delicate chemical filtration.

- Cost-Effective Maintenance: Knitted mesh filters are generally easy to clean and maintain, which helps in reducing operational costs over their lifespan.

- High Surface Area: The knitted structure provides a large surface area for filtration, enhancing the capture of particles and increasing the efficiency of the filtration process.

- Resistance to Environmental Factors: Depending on the material, these filters offer resistance to corrosion, high temperatures, and chemical reactions, making them suitable for challenging operational environments.

- Improved Safety: Especially in applications like cooking and industrial exhausts, these filters effectively trap grease, oil, and other combustible particles, reducing the risk of fire hazards.

- Energy Efficiency: By maintaining low resistance and high filtration capacity, these filters contribute to the energy efficiency of the systems they are integrated into, which is crucial for sustainable operations.

Uses of Knitted Mesh Filters

- Oil and Gas Industry: In the petroleum sector, these filters are used for the efficient separation of oil and gas mixtures, ensuring the purity of extracted resources.

- Chemical Processing: Knitted mesh filters play a crucial role in the chemical industry, filtering out impurities and protecting equipment from particulate contamination.

- Air and Gas Filtration: They are used in air filtration systems to remove particles and contaminants, ensuring cleaner air output in various environments, including industrial and residential settings.

- Automotive Industry: In automotive applications, these filters are used in exhaust and emission control systems to capture particulates and pollutants.

- Food and Beverage Processing: These filters are instrumental in food and beverage production, where they ensure the purity and quality of products by removing unwanted particles from liquids and gases.

- Pharmaceuticals: In the pharmaceutical industry, they are used for the precise filtration of air and gases, which is critical in maintaining sterile environments for drug production.

- Water Treatment: Knitted mesh filters are used in water treatment plants for the removal of solids, aiding in the purification and treatment of water for various uses.

Product Photo Showcase and Alias

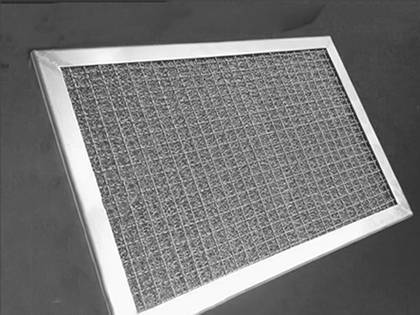

Round Wire Knitted Mesh Filter

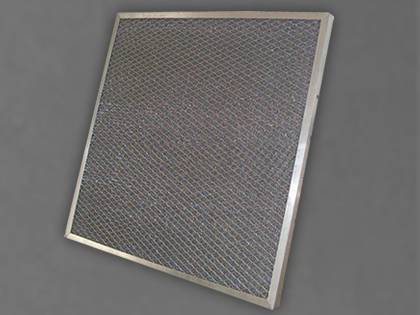

Flat Wire Knitted Mesh Filter

Crimped Wire Mesh Grill Knitted Mesh Filter

Expanded Metal Grill Knitted Mesh Filter

Welded Wire Mesh Grill Knitted Mesh Filter

Polypropylene Knitted Mesh Filter

Oil Mist Eliminators: Primarily used in the petroleum industry, Oil Mist Eliminators capture and remove fine oil droplets from air or gas streams, ensuring the purity of extracted resources and protecting equipment.

Air Filtration Meshes: Air Filtration Meshes are integral to air purification systems, effectively removing airborne particles and contaminants to ensure cleaner, healthier air in various settings.

Exhaust Filters: Commonly used in automotive and industrial exhaust systems, Exhaust Filters capture pollutants and particulates, contributing to emission control and environmental protection.

Beverage Filtration Screens: In food and beverage production, these screens are crucial for removing unwanted particles, ensuring the quality and safety of consumable products.

Pharmaceutical Air Filters: Specifically designed for the pharmaceutical sector, these filters are key in maintaining sterile air conditions essential for the production of pharmaceuticals.

Water Treatment Meshes: Employed in water treatment facilities, Water Treatment Meshes aid in the removal of solids and impurities, playing a vital role in water purification processes.