JD Hardware Wire Mesh Co., Ltd offers a diverse range of Y Strainer Screens, ideal for efficient filtration in various industrial applications. These screens are expertly designed to remove unwanted materials, ensuring device protection and optimal performance. Known for easy installation, they are suited for many environments. We provide customizable screens to meet specific industrial requirements, maintaining a commitment to quality and affordability.

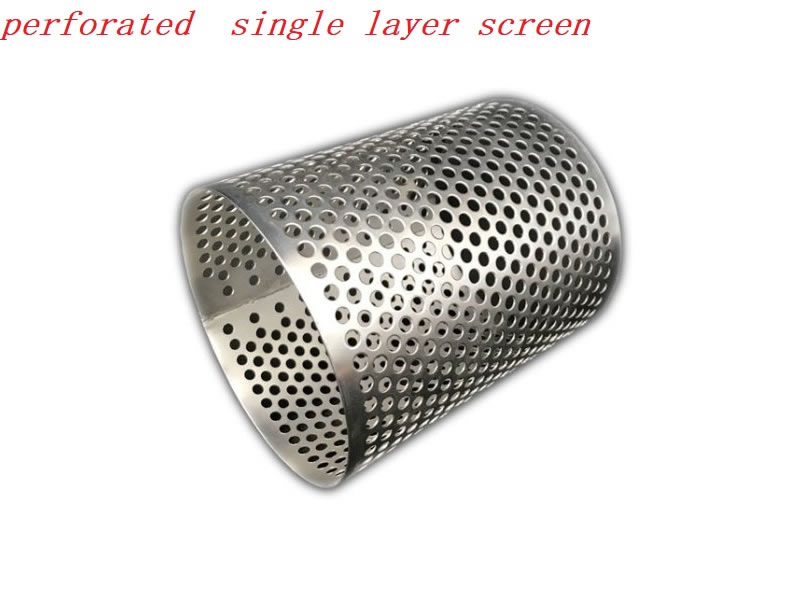

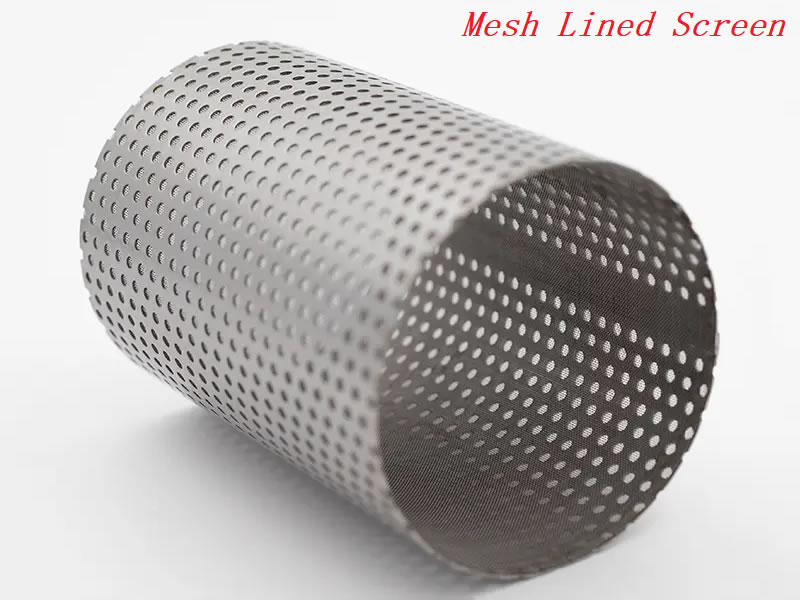

Our selection includes screens made from different materials to match specific filtration needs. Wire cloth screens are perfect for finer filtration in small strainers, effectively removing small particles. For larger strainers needing coarser filtration, our robust perforated metal screens are ideal, effectively capturing larger debris. We also offer a combination of perforated metal lined with stainless steel mesh for fine filtration tasks, offering both durability and precision. This design ensures comprehensive filtration without compromising screen integrity.

Y Strainer Screen Specifications and Customization

JD Hardware Wire Mesh Co., Ltd offers extensive customization capabilities for Y Strainer Screens, ensuring that each screen can be precisely tailored to meet the specific requirements of various industrial applications.

- Material Options: Y Strainer Screens from JD Hardware Wire Mesh Co., Ltd are available in various materials including stainless steel grades 304, 316, and 316L, as well as galvanized steel and other alloy options. This range of materials allows for optimal selection based on the specific environmental and chemical exposure of the application.

- Filtration Construction: The construction of these screens varies from single-layer options, which utilize either wire cloth or perforated metals, to multilayer configurations. The multilayer screens typically feature perforated metals on the outside with a wire cloth lining, offering enhanced filtration capabilities.

- Standard Sizes and Customization: Our Y Strainer Screens are available in standard sizes such as DN15 (1629mm), DN20 (2033mm), DN25 (2540mm), DN32 (3150mm), DN40 (4055mm), and DN50 (4358mm). Additionally, we provide customization options to tailor the screens to specific dimensions as required by the client.

- Mesh Specifications for Various Applications: For water supply networks, we generally offer screens in the range of 18-30 mesh. Ventilation networks typically use screens within 10-100 mesh, and for oil supply networks, the mesh range is from 100-480. This flexibility ensures that clients can select the appropriate mesh size for their specific filtration needs.

- Filtration Range and End Finish: The wire cloth for these screens is available from 2mesh up to 500mesh, and perforated screens range from 0.4mm up to 1 inch. End finishes can be customized to include U edging, flange edging, or a simple edgeless design, based on the installation and operational requirements.

Y Strainer Screens Advantages

- Effective Contaminant Removal: Designed to filter a wide range of particle types and sizes, these screens are ideal for use in water, ventilation, and oil networks, enhancing fluid purity and quality.

- Built to Last: The use of high-quality materials and solid construction means these screens endure tough industrial conditions, minimizing the need for replacements and upkeep.

- System Protection: They effectively remove harmful particles, safeguarding sensitive components in various systems and reducing operational interruptions and maintenance.

- Economical Over Time: Designed for durability and reusability, these screens are a cost-saving filtration solution, cutting down long-term operational expenses.

- Advanced and Efficient: Y Strainer Screens are known for their advanced structure, minimal resistance, and easy blowdown, making them a practical and efficient choice for various applications. Their sturdy build, resistance to corrosion and rust, and ease of cleaning further add to their appeal.

Application of Y Strainer Screen

- Installation and Positioning: Y Strainer Screens are typically installed at the inlet end of various valves, such as pressure reducing valves, pressure relief valves, and constant water level valves. This strategic placement is key to their functionality in various systems.

- Filtration Function: The primary role of these screens is to filter mechanical impurities present in the medium. They effectively capture and remove elements like rust and sand particles from sewage, as well as a small number of solid particles in liquids.

- Protection of Equipment: By filtering out these impurities, Y Strainer Screens play a vital role in protecting the accessories within equipment pipelines. This protection extends to preventing wear and blockage in the system, thereby ensuring the smooth and efficient operation of the equipment.

Product Photo Showcase and Alias

Industrial Process Strainers: Used in manufacturing and industrial processes to remove solid particles from liquids and gases. They are essential in protecting equipment from potential damage caused by debris.

Water Pipeline Strainers: Installed in water pipelines to filter out sediments and impurities, ensuring clean water supply for various applications, including residential, commercial, and industrial uses.

Chemical Strainers: Designed for use in the chemical industry, these strainers handle aggressive chemicals and high temperatures, made from materials resistant to corrosion and chemical damage.

Oil and Gas Strainers: Used in the oil and gas industry to filter out impurities from crude oil and natural gas. They play a crucial role in preventing clogging and damage to downstream equipment.

Food and Beverage Strainers: Employed in the food and beverage industry to ensure that products are free from unwanted particles. They must comply with strict hygiene and safety standards.

Steam Strainers: Used in steam lines to trap particles that could damage equipment or affect the quality of the steam. They are crucial in power plants and heating systems.

Marine Strainers: Designed for use in marine environments, these strainers handle seawater and are made from materials that resist corrosion and saltwater damage.

Pharmaceutical Strainers: Used in the pharmaceutical industry to ensure the purity of products. They must meet stringent health and safety standards.

Sanitary Strainers: Specifically designed for sanitary applications, such as in hospitals or laboratories, where sterility and cleanliness are paramount. They are made from materials that are easy to clean and sterilize.