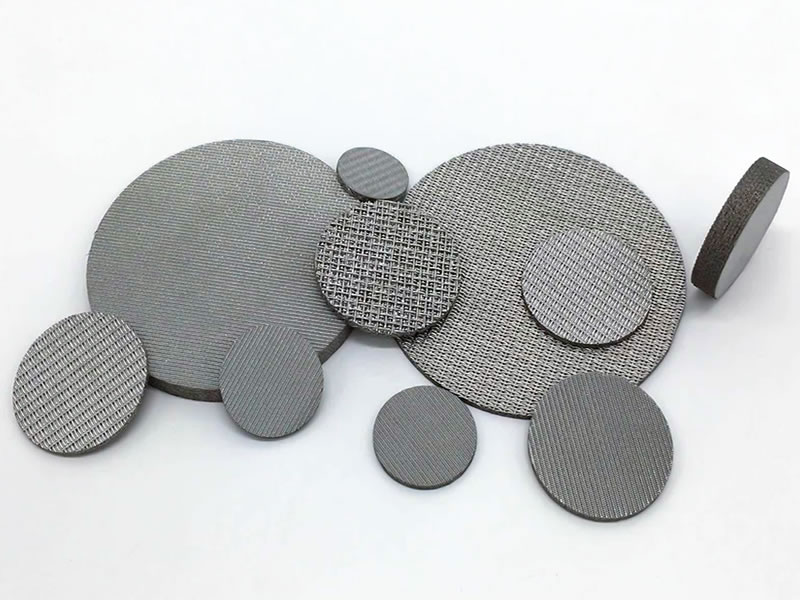

JD Hardware Wire Mesh Co., Ltd offers a comprehensive range of Sintered Mesh Filter Discs, engineered to meet diverse industrial requirements. Our collection includes everything from simple round cuts to complex disc assemblies with multiple sections, frames, and mesh layers. This extensive variety caters to the specific needs of different industries. JD Hardware Wire Mesh Co., Ltd is dedicated to providing quality, precision, and versatility with our Sintered Mesh Filter Discs, ensuring we meet the continuously evolving and diverse needs of our customers.

Fabrication Techniques

Our fabrication process is customized to the unique specifications of each product. We utilize state-of-the-art stamping machines for producing slim, high-volume discs, ensuring both speed and cost-effectiveness. For discs requiring greater thickness, larger diameters, or intricate designs, our skilled technicians use precision laser cutting. For products needing ultra-precise dimensions, we employ Electrical Discharge Machining (EDM) cutting, known for its exceptional accuracy, albeit more time-intensive and expensive.

Material Options

Our Sintered Mesh Filter Discs are available in various materials, including stainless steel grades like 304, 304L, 316, 316L, 904L, and 310S; Duplex grades 2205 and 2507; Monel 400; Inconel 601; and Hastelloy variants C276 and C2. This diverse range ensures suitability for a wide array of industrial applications.

Micron Rating

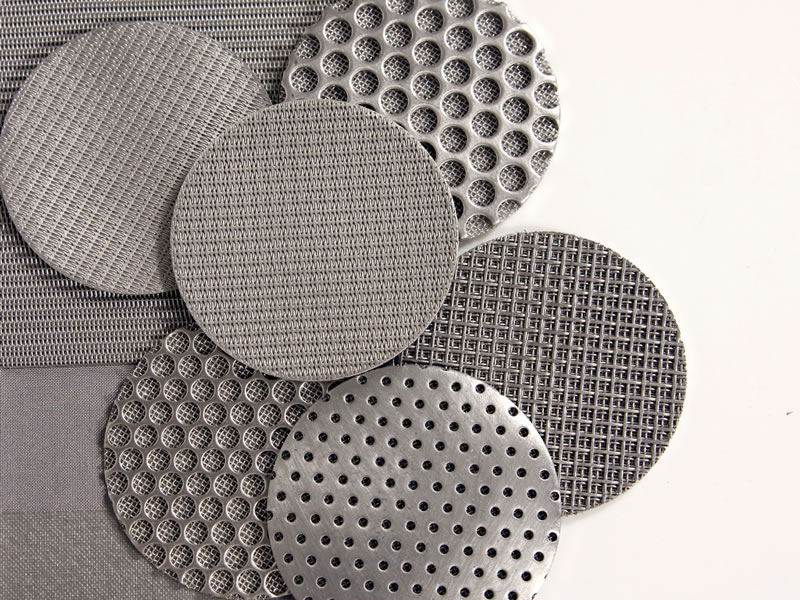

The micron ratings of our filter discs are highly versatile, with standard options ranging from 1 to 200 microns. We specifically offer 1, 2, 5, 10, 15, 20, 30, 40, 50, 80, 100, 150, and 200 micron ratings. Customization of the micron rating and filter cloth is also available to meet specific client requirements.

Diameter Range

Standard production sizes for our discs range from a minimum of 10mm to a maximum of 3000mm. We have the capability to exceed these dimensions, as the sintered mesh filter media can be connected via welding for larger diameters as per client needs.

Thickness Variability

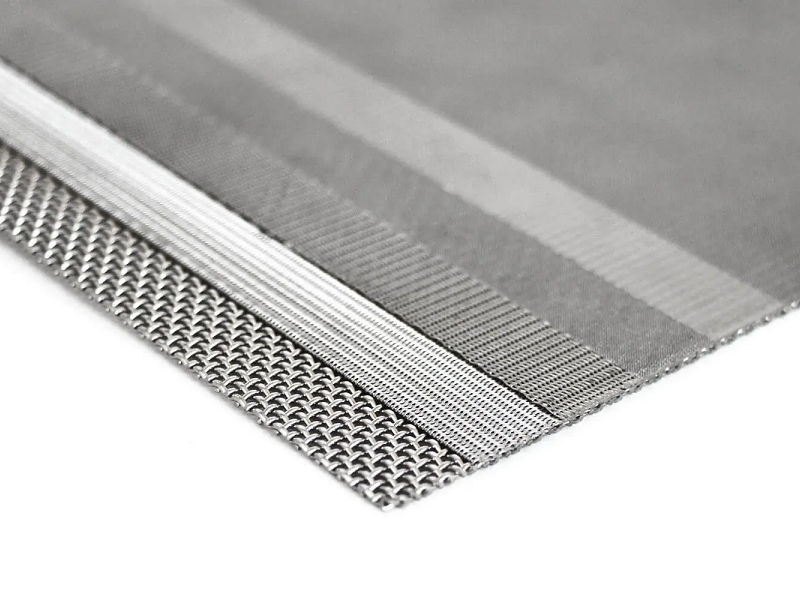

The thickness of our sintered mesh filter discs varies based on application needs, ranging from below 1mm to over 20mm. This is dependent on the structure of the sintered mesh layers, allowing us to cater to both lightweight and heavy-duty applications.

Customization and Support

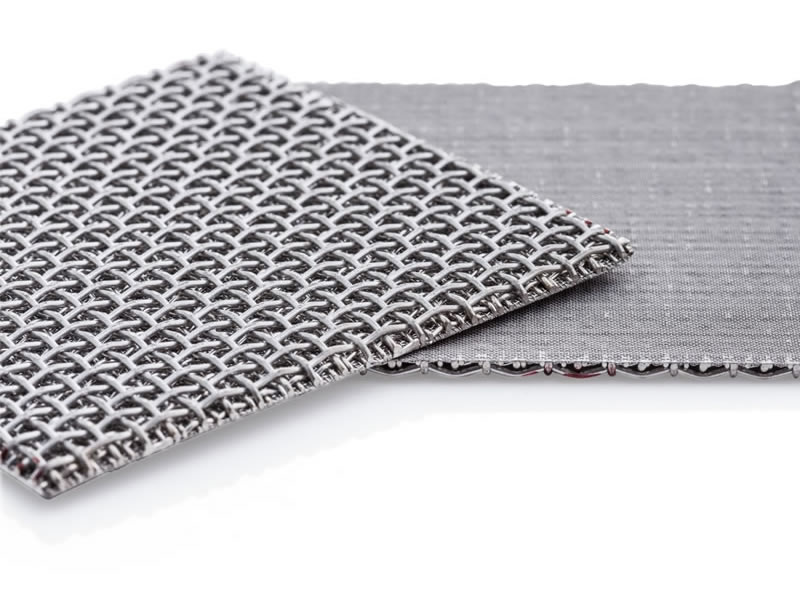

Customization is a key aspect of our offerings. Our sintered wire mesh can be adapted to various thicknesses and performance requirements. We provide multi-layered meshes for specific applications like flame suppression or noise reduction. A popular choice is the sintered wire mesh reinforced with perforated metal, which often eliminates the need for additional metal frames.

Mesh Replacement Service

We offer a cost-effective mesh replacement service for larger diameter discs with heavy metal frames. This allows for the replacement of only the worn or damaged mesh while reusing the frames, offering a sustainable and economical solution for large-scale operations.

Sintered Mesh Filter Discs Feature

The Sintered Mesh Filter Discs are distinguished by their exceptional features, offering high rigidity and stability, which make them robust for various industrial applications. They are designed to withstand heat and wear, ensuring durability and longevity. These discs are highly valued for their cleanability and reusability, making them both economical and environmentally friendly. With a good dirt holding capacity, they efficiently retain impurities while maintaining consistent performance. The ease of cleaning and the ability to reuse these filters contribute to their practicality in continuous use scenarios. Importantly, the geometrical structure of the mesh is preserved even after extensive use, ensuring consistent filtration quality. This leads to a long service life, significantly reducing downtime and enhancing operational efficiency.

Application

Sintered mesh filter discs are used in several applications, including protecting equipment inlets, acting as flame arresters, and aiding in extraction filter equipment. They are also key in Nutsch filters and agitator dryers, especially in 3 in 1 filter systems. Additionally, these discs are used in filter-reactor setups and chromatography columns for effective substance separation and purification.

Product Photo Showcase and Alias

Sintered Filter Discs for Equipment Protection: These discs are specifically designed to safeguard machinery by filtering out harmful particles at the equipment’s inlet, ensuring only clean and safe materials enter the system.

Sintered Flame Arrester Discs: Tailored for fire safety, these discs prevent the spread of flames in systems, acting as critical barriers in hazardous environments.

Sintered Extraction Filter Discs: Utilized in extraction equipment, these discs are essential for separating and refining substances, ensuring purity and effectiveness in extraction processes.

Sintered Filter-Reactor Discs: Optimized for use in filter and reactor setups, these discs play a key role in the separation and reaction process, enhancing the efficiency of chemical processing.

Sintered Chromatography Filter Discs: In chromatography columns, these discs are crucial for the purification and analysis of chemical compounds, ensuring accurate and reliable results in chromatographic separation.

Sintered Air Filtration Discs: These discs are designed for air filtration systems, effectively removing contaminants and ensuring the purity of air in various environments.

Sintered Liquid Filtration Discs: Tailored for liquid filtration applications, these discs excel in removing impurities from liquids, essential in various industrial and laboratory processes.

Sintered Gas Filtration Discs: Specifically designed for gas filtration, these discs efficiently separate and purify gases, crucial in various industrial applications where gas purity is paramount.