Supplier of Silver, Tantalum, Tungsten, and Molybdenum Wire Mesh

JD Hardware Wire Mesh Co., Ltd specializes in producing and exporting wire mesh woven from various special alloys. These alloys are designed for high-performance applications and can be ordered on a special basis. Our range includes several in-demand special alloys as well as some uncommon stainless steel alloys. Each alloy in our selection is chosen for its distinct properties, ensuring they fulfill specific industrial requirements. Whether it’s providing increased corrosion resistance, improved strength, or specific electrical or thermal conductivities, our special alloy wire meshes are built to excel in challenging environments. We welcome inquiries from customers with unique requirements beyond our existing alloy range and are ready to offer additional information about our available options. Our commitment lies in addressing diverse industrial needs with our precision-engineered wire mesh solutions.

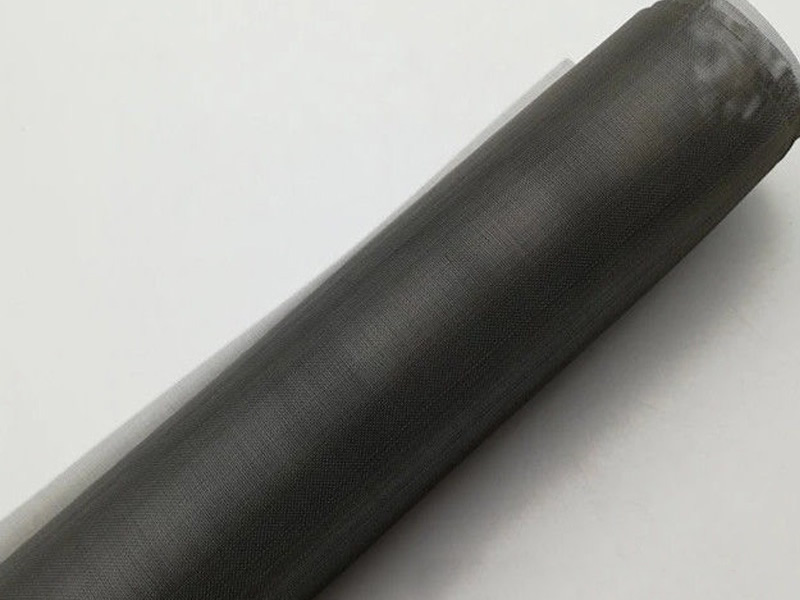

Molybdenum Wire Mesh

Primarily composed of 99.95% molybdenum with trace elements, this metal is highly versatile, especially in high-temperature environments. Molybdenum wire mesh is ductile and has a high melting point, making it suitable for heating elements and electronic applications.

Specifications

- Material Options: Our Molybdenum wire mesh is available in two types: pure Molybdenum wire and Molybdenum alloy wire, offering robustness for various applications.

- Wire Diameter Range: The wire diameter spans from 0.02 mm to 4.87 mm, allowing for customization according to specific strength and flexibility needs.

- Purity Levels: We provide high-purity Molybdenum wire mesh ranging from 99.95% to 99.98%, ensuring superior quality and performance.

- Melting Point: With a melting point of 2622 ±10°C, our mesh can withstand extremely high temperatures, making it ideal for demanding environments.

- Density and Thermal Conductivity: The mesh has a density of 10.22 g/cm3 and a thermal conductivity of 1.397000 watts/cm/Deg. C, making it suitable for thermal management applications.

- Mesh Size Variety:

Available in sizes from 1 to 400 mesh, with standard sizing options ranging between 2 and 280 mesh, catering to a wide array of requirements. - Weave Types: We offer plain weave, twill weave, and dutch weave, providing different structural and aesthetic qualities.

- Hole Patterns: The mesh comes in various hole patterns, including square and rectangular, to suit diverse application needs.

- Surface Treatment Options: Our mesh can be treated with black-pure or graphite coating for additional protection and enhanced properties.

- Dimensions: Widths range from 0.3 to 2 meters and lengths from 10 to 100 meters, accommodating large-scale and precise applications.

- Feature:

Molybdenum mesh features the highest melting point, low density, minimal vapor pressure, limited thermal expansion, high temperature strength, acid-alkali-wear resistance, greater ductility than tungsten, excellent filtering performance, and good electrical and thermal conductivity. - Application:

Molybdenum mesh is widely used in such various fields, e.g. furnace, petroleum, chemical, food, medical, machinery and so on. The mainly usage is filtering, sieving, heating element and other special purpose. - Chemical Composition of Molybdenum:

| Molybdenum (Mo) | 99.9% (for pure molybdenum) |

| Titanium (Ti) | 0.1% – 0.5% (in alloys) |

| Zirconium (Zr) | 0.1% – 0.5% (in alloys) |

| Carbon (C) | 0.01% – 0.04% (in carbide form) |

| Iron (Fe) | 0.01% – 0.1% (in alloys) |

| Nickel (Ni) | 0.01% – 0.1% (in alloys) |

| Copper (Cu) | 0.01% – 0.1% (in alloys) |

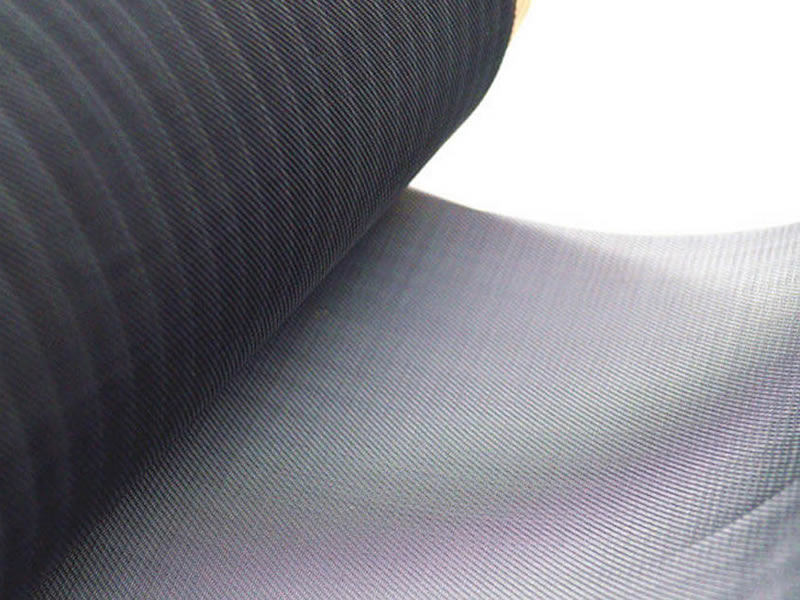

Tungsten Wire Mesh

Woven from pure, non-alloyed tungsten wire, tungsten wire mesh is available in both bright and black tungsten forms. This mesh combines tungsten’s natural properties, including resistance to high temperatures, a low rate of evaporation, and robust tensile strength. It excels in applications requiring heat and electrical resistance, making it a top choice for radiation shielding and vacuum furnace heating elements. Additionally, its high density and resistance to corrosion render it effective for filtration and sieving in acidic or alkaline environments.

Specifications

- Material Variants: Our Tungsten wire mesh is crafted from both bright and black pure tungsten wire, ensuring a high-quality product.

- Tungsten Purity and Physical Properties: The tungsten content in our mesh is over 99.95%, guaranteeing exceptional purity. It has a high density of 19.25 g/cm³, contributing to its strength and durability. The mesh withstands extreme temperatures with a melting point of 3410 ±20°C and a boiling point of 5660°C.

- Wire Diameter and Mesh Size: Wire diameters range from 0.01 mm to 2.0 mm, accommodating a broad spectrum of applications. Available mesh sizes span from 1 to 400 mesh, offering versatility in filtration and screening uses.

- Techniques and Weave Types: The mesh is produced using woven and knitted techniques, providing different structural characteristics. We offer plain and twill weaves, each lending unique texture and strength properties.

- Color and Dimensions: Color options include silvery-white and silver-gray, suitable for various aesthetic preferences. Widths range from 0.1 to 2 meters, and lengths from 10 to 100 meters, catering to diverse project scales.

- Feature: Tungsten wire mesh is notable for its extreme melting point, exceptional tensile strength, and very low vapor pressure. It’s highly dense, heat-resistant, hard, and tough, offering excellent filtering performance and resistance to acid and alkali corrosion, all while maintaining a smooth, unbroken surface.

- Application: Tungsten wire mesh, known for its high-temperature tolerance, strength, and corrosion resistance, is widely used for radiation shielding, heating elements in vacuum furnaces, and as a filter in acidic or alkaline environments.

Tantalum Wire Mesh

Tantalum wire mesh, with a melting point and density between those of tungsten and molybdenum meshes, is made from tantalum wire, originating from tantalum powder. This rare metal mesh is essential in applications like chemical liquid filtering, vacuum furnace grates, and electronic component production due to its stable chemical properties and strong corrosion resistance. It withstands temperatures up to 150°C without chemical degradation, comparable to glass in corrosion resistance. Its excellent ductility allows for versatile installation, and with a melting point of 2996°C, one of the highest among refractory metals, it’s ideal for electronic engineering and heat treatment.

Specifications

- Material Variants: Our Tantalum wire mesh is primarily made from tantalum wire, with options available in molybdenum alloy wire, catering to diverse application needs.

- Wire Diameter and Melting Point: The wire diameter ranges from 0.01 mm to 4.87 mm, allowing for precise customization based on specific requirements. With a high melting point of 2996°C, our mesh is suitable for high-temperature applications.

- Density and Mesh Size: The mesh has a density of 16.69 g/cm³, contributing to its durability and strength. Available in mesh sizes from 1 to 150 mesh, it offers versatility in both industrial and technical uses.

- Techniques and Weave Types: We utilize various techniques including woven, expanded, and perforated methods to create different structural features. The mesh is available in plain weave, twill weave, and dutch weave, each providing unique textural characteristics.

- Color and Dimensions: The mesh comes in a distinctive light blue color, adding an aesthetic dimension to its functional properties. We offer widths ranging from 0.3 to 2 meters and lengths from 10 to 100 meters, accommodating a wide range of project sizes.

- Feature: Tungsten wire mesh features the highest melting point and low density, coupled with strong corrosion resistance, ductility, and toughness. It offers excellent filtering performance and is resistant to acids, alkalis, and wear.

- Application: Tantalum wire mesh is widely used for chemical liquid filtration, in vacuum furnace grates, and for producing electronic components.

- Chemical composition of Tantalum wire mesh

| Element | Percentage (%) |

| Tantalum (Ta) | ≥ 99.9% |

| Iron (Fe) | ≤ 0.01% |

| Nickel (Ni) | ≤ 0.01% |

| Chromium (Cr) | ≤ 0.01% |

| Molybdenum (Mo) | ≤ 0.02% |

| Niobium (Nb) | ≤ 0.1% |

| Titanium (Ti) | ≤ 0.01% |

| Tungsten (W) | ≤ 0.01% |

| Silicon (Si) | ≤ 0.005% |

| Manganese (Mn) | ≤ 0.005% |

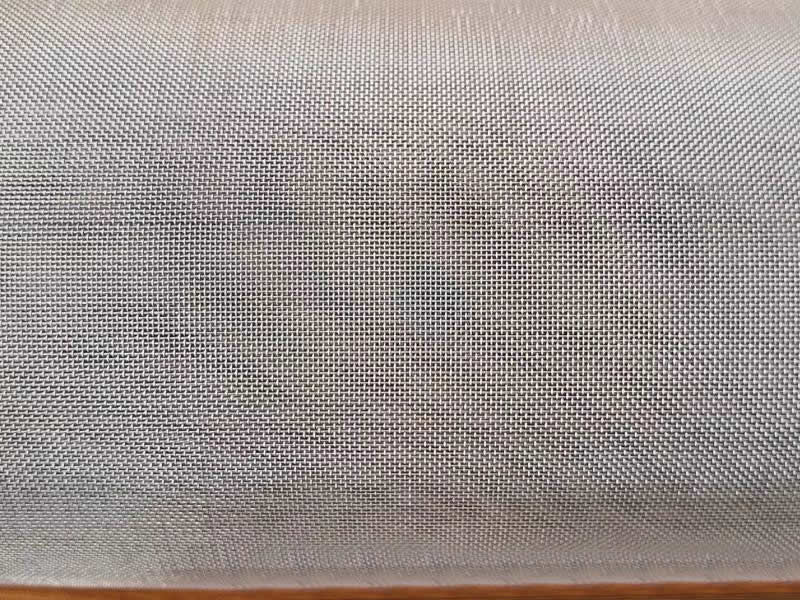

Silver Wire Mesh

Made from 99.99% pure silver, this wire mesh is woven in plain or twill patterns and can also be expanded into diamond shapes. Its excellent electrical and thermal conductivity, along with chemical stability and ductility, make it ideal for electronic uses like electrode and battery collector mesh, as well as for high-precision filters. Additionally, silver wire mesh is used in art and decoration.

Specifications

- Material and Chemical Composition: Our Silver wire mesh is crafted from silver wire with a chemical composition of 99.95% Ag (Silver), 0.05% Cu (Copper), 0.002% P (Phosphorus), and a total of 0.010% other volatile impurities. This composition ensures high purity and quality.

- Wire Diameter: The wire diameters available range from 0.15 mm to 0.35 mm, providing flexibility in design and application.

- Technique and Weave Types: Produced using a woven technique, our mesh offers durability and consistency. Available in both plain weave and twill weave, each providing a unique mesh structure and appearance.

- Dimensions: Roll width varies between 0.3 meters to 2 meters, accommodating a range of project sizes. Roll lengths are available from 10 meters up to 30 meters, ensuring sufficient material for both small-scale and large-scale applications.

- Feature:Silver wire mesh features 99.99% purity, excellent electrical and thermal conductivity, stable chemical properties, ductility, and a high recovery value.

- Application:Silver wire mesh, known for its electrical and thermal conductivity, is widely used in electronics as electrode and battery collector mesh, and also in high-precision filtration equipment.

Wire Mesh of Other Materials

- T-310 SS Wire Mesh: T-310 SS wire mesh, commonly custom-manufactured to meet specific requirements, stands out for its remarkable high-temperature properties, combined with excellent ductility and weldability. This makes it an ideal choice for applications that demand resilience to extreme heat. It’s particularly valued in industries where materials are exposed to high temperatures regularly, such as in furnace linings and thermal processing plants. Its toughness under such conditions ensures reliability and longevity, making it a preferred option for those seeking durability and strength in high-heat environments.

- T-321 SS Wire Mesh: T-321 SS wire mesh, often custom produced, is an austenitic 18/8 steel, uniquely stabilized with titanium. This stabilization not only confers it with similar resistance to general corrosion as seen in T-304 SS but also enhances its structural integrity in challenging environments. It’s frequently used in the manufacturing of oil refinery equipment and welded pressure vessels. Its robustness against corrosion makes it a reliable material in the petrochemical industry, where it offers enduring performance in both structural and corrosive settings, providing a blend of durability and resistance.

- T-347 SS Wire Mesh: T-347 SS wire mesh is generally custom-made and is an austenitic 18/8 steel, stabilized by niobium and tantalum. These stabilizing elements marginally improve its corrosion resistance in certain conditions, offering a slight edge in challenging environments. Common applications include high-temperature gaskets and chemical product equipment, where its improved corrosion resistance is beneficial. This type of mesh is particularly suited for use in chemical processing industries and high-temperature applications, providing an optimal balance of corrosion resistance and structural integrity.

- T-430 SS Wire Mesh: Custom manufacturing is often required for T-430 SS wire mesh, a basic ferritic, non-heat treatable stainless steel known for its good corrosion and oxidation resistance. This type of mesh is well-suited for various industrial applications, including plant equipment and oil-refinery equipment. Its resistance to corrosion and oxidation makes it particularly valuable in environments where these factors are a concern, ensuring stability and longevity. The mesh’s durability and resistance to environmental factors make it a practical choice for industries requiring materials that can withstand challenging conditions while maintaining their structural and functional integrity.