JD Hardware Wire Mesh Co., Ltd offers a state-of-the-art Polymer Leaf Disc Filter, designed to efficiently handle the filtration of high-viscosity substances. This product stands out for its ability to effectively tackle challenges such as polymer stagnation, degradation, and gel formation. Engineered with multiple sintered layers and a durable central hub, the Polymer Leaf Disc Filter guarantees longevity and cost-effectiveness in its operation.

Innovatively designed, the filter enables filtration from both the top and bottom, significantly increasing the filtration area and supporting high flow rates. This feature not only enhances the efficiency of the filtering process but also contributes to the overall performance and reliability of the filter.

With a focus on quality and technological advancement, JD Hardware Wire Mesh Co., Ltd ensures that the Polymer Leaf Disc Filter meets the highest standards of the industry. The company’s dedication to excellence in mesh and filtration technology, combined with a commitment to customer satisfaction, positions JD Hardware Wire Mesh Co., Ltd as a reliable provider of effective filtration solutions for various industrial needs.

Common specifications and sizes

- Material Composition: Comprised of high-quality polymer and options like SS316 or 316L alloys, ideal for high-viscosity filtration applications.

- Filter Construction: Incorporates 5-7 sintered layers and a central hub, ensuring structural integrity.

- Filtration Capability: Capable of reducing polymer stagnation and degradation by up to 95%.

- Design Features: Offers a filtration area expansion of 30-40%, thanks to its dual-action design.

- Flow Rate: Supports flow rates ranging from 100 to 500 liters per minute.

- Dimensions: Available in sizes ranging from 5 cm to 50 cm in diameter.

- Operating Conditions: Operates efficiently in temperatures ranging from -20°C to 80°C.

- Longevity: Designed for a service life of up to 5 years under normal operating conditions.

- Filter Rating: 1-100 microns

- Maximum Operational Pressure Drop: 10 MPa

- Maximum Operational Temperature: 300℃

- Filter Material Viscosity: Up to 260 Pa.s

- Maximum Operational Pressure: 31.7 MPa

- Cost Efficiency: Reduces operational costs by approximately 20-30% compared to standard filters.

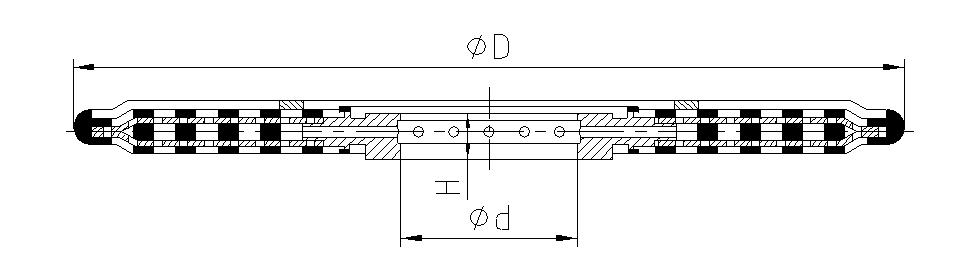

- Outer Diameter (OD): Range in mm: 152.4 – 304.8 mm, Range in inches: 6″ – 12″

- Inner Diameter (ID): Range: 38.2 – 85 mm

- Thickness: Range: 6.5 – 8 mm

- Filtration Area: Range: 0.032 – 0.13 square meters

- Dimension of polymer leaf disc filter:

| 4inch | 5inch | 6inch | 7inch | 8inch | 10inch | 12inch | |

| OD(mm) | 111 | 149 | 152.4 | 177.8 | 222 | 254 | 304.8 |

| ID(mm) | 47.6 | 47.6 | 38.2 | 63.5 | 76.2 | 85 | 115.5 |

| 38.1 | 38.1 | 47.6 | 63.5 | 47.6 | 85.2 | ||

| 47.6 | 76.2 | ||||||

| 63.5 | |||||||

| Remarks: Other dimensions could also be customized, such as OD 181mm/ OD 297mm. | |||||||

Features

- High-Viscosity Filtration: Optimized for filtering substances with high viscosity, ensuring effective separation and clarity.

- Advanced Layering: Features multiple sintered layers for improved filtration efficiency and strength.

- Dual Filtration Design: Equipped with a unique design that allows both top and bottom filtration, enhancing the overall filtration area and capacity.

- High Flow Rate Compatibility: Designed to support high flow rates, making it suitable for demanding industrial applications.

- Versatile Applications: Suitable for a wide range of industrial processes, particularly where high-viscosity fluid handling is essential.

Product Also Known As

Polymer Sintered Filter: Emphasizes its application in filtering polymers through a sintered mechanism for enhanced purification.

High-Viscosity Substance Filter: Highlights its specialization in filtering substances with high viscosity levels.

Polymer Leaf Disc Filter: Underlines its use in various industrial applications involving polymer substances.

Multi-Layer Polymer Filter: Refers to its multiple-layer design, enhancing its filtration efficiency for polymers.

High-Flow Polymer Filter: Indicates its capacity to handle high flow rates in polymer filtration processes.

Dual-Direction Polymer Filter: Describes its feature of filtering from both top and bottom, beneficial in polymer processing.

High-Temperature Polymer Filter: Suitable for applications involving high temperatures, particularly in polymer filtration.

Pressure-Resistant Polymer Filter: Designed to withstand high pressures, making it ideal for certain polymer filtration tasks.

Polymer Disc Filtration System: Denotes its disc-shaped design used specifically in the filtration of polymer materials.