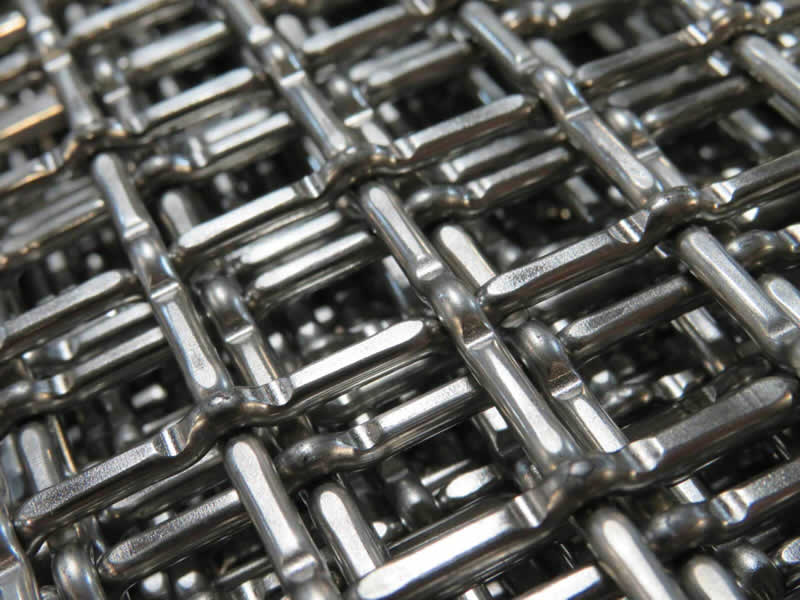

JD Hardware Wire Mesh Co., Ltd specializes in the production and export of Stainless Steel Crimped Wire Mesh products. Our stainless steel crimped mesh is crafted using wires that are crimped before weaving, ensuring stability and uniformity in meshes with larger spaces. This pre-crimping process enhances the structural integrity of the mesh. With a variety of crimping styles, our products not only meet manufacturing efficiency but also serve functional and aesthetic purposes. Our crimped wire mesh is ideal for a range of applications, providing reliable performance and a pleasing appearance.

General Specifications

Material Options:

- Stainless Steel Grades: Available in 304, 304L, 316, and 316L, catering to different environmental and application needs.

- Special Alloys: Options include 310 stainless steel, Titanium mesh, Nickel Mesh, Monel wire mesh, and Chrome alloy iron, each providing unique properties for specialized applications.

Wire Diameter Range:

- Variety: Ranging from 0.5mm to 12.7mm, allowing for a selection of mesh strengths and flexibility levels.

Aperture Sizes:

- Range: Available from 1.0mm to 100mm, accommodating a wide spectrum of filtration, separation, and protective functions.

Roll Widths:

- Standard Sizes: Commonly offered in widths of 40″, 48″, and 60″.

- Extended Options: Available up to 4 meters, catering to larger scale applications and installations.

Roll Lengths:

- Standard Lengths: Typically available in lengths of 15m and 30m.

- Extended Rolls: Can extend up to 100 feet.

- Customization: Special sizes can be tailored to meet specific project requirements, providing flexibility for unique applications.

Customized Sizes

This diverse range in material, size, and customization makes Stainless Steel Crimped Wire Mesh a versatile solution for numerous industrial, architectural, and specialized applications.

| Mesh | Open Area | Wire Diameter | Weaving methods | ||

| inch | mm | Max(mm) | Min(mm) | ||

| 4″ | 4 | 101.6 | 12.7 | 6 | Intercrimp/Lock |

| 3″ | 3 | 76.2 | 12.7 | 5 | Intercrimp/Lock |

| 2″ | 2 | 50.8 | 10 | 4 | Intercrimp/Lock |

| 1 1/2″ | 2 | 38.1 | 10 | 3 | Intercrimp/Lock |

| 1X2″ | 1X2 | 25.4X50.8 | 8 | 2.5 | Intercrimp/Lock |

| 1″ | 1 | 25.4 | 8 | 2 | Plain /Intercrimp |

| 3X4″ | 0.75 | 19.05 | 6 | 1.8 | Plain /Intercrimp |

| 5X8″ | 0.62 | 15.8 | 5 | 1.5 | Plain /Intercrimp |

| 2 | 0.5 | 12.7 | 4 | 1 | Plain /Intercrimp |

| 3 | 0.33 | 8.46 | 3 | 1 | Plain /Intercrimp |

| 4 | 0.25 | 6.35 | 2 | 0.8 | Plain /Intercrimp |

| 5 | 0.2 | 5.08 | 1.6 | 0.7 | Plain /Intercrimp |

| 6 | 0.17 | 4.23 | 1.5 | 0.6 | Plain /Intercrimp |

| 8 | 0.12 | 3.17 | 1.2 | 0.7 | Plain /Intercrimp |

| 10 | 0.1 | 2.54 | 1 | 0.6 | Plain |

| 12 | 0.08 | 2.11 | 0.9 | 0.5 | Plain |

| 14 | 0.07 | 1.81 | 0.7 | 0.5 | Plain |

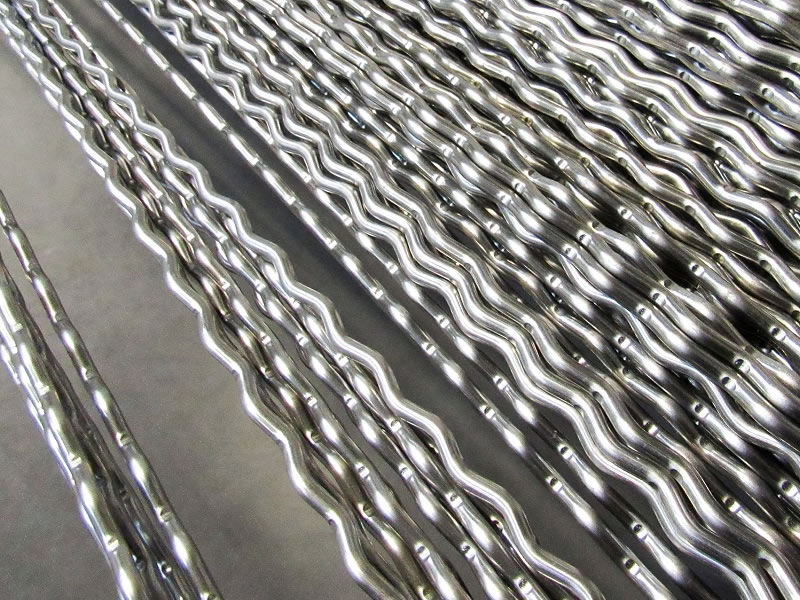

Stainless Steel Crimped Mesh Weaving Processes

All these methods involve pre-crimping wires before weaving, yet each serves a unique purpose. Plain crimped is versatile for general use, double crimped increases strength for heavy-duty tasks, flat top ensures a smooth surface for handling, and lock crimped offers both aesthetic and structural robustness. Each type is designed to meet specific needs in industrial, architectural, and screening applications.

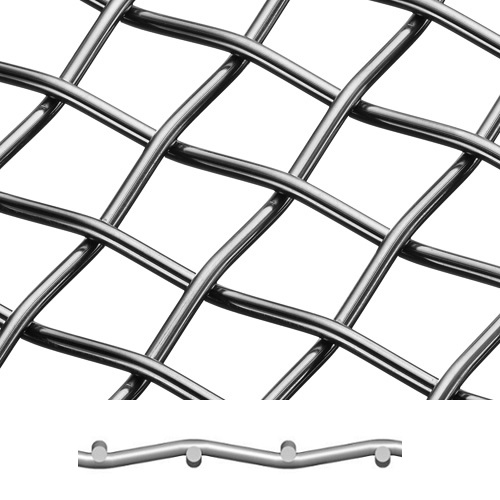

Plain Crimped Wire Mesh Process

This technique involves pre-crimping each wire before weaving in a simple over-and-under pattern. Uniform crimping across the mesh ensures a consistent and traditional weave. This method strikes a balance between rigidity and flexibility, making it suitable for diverse applications. It’s commonly used in basic screening, fencing, and architectural accents, where a classic look and moderate strength are desired.

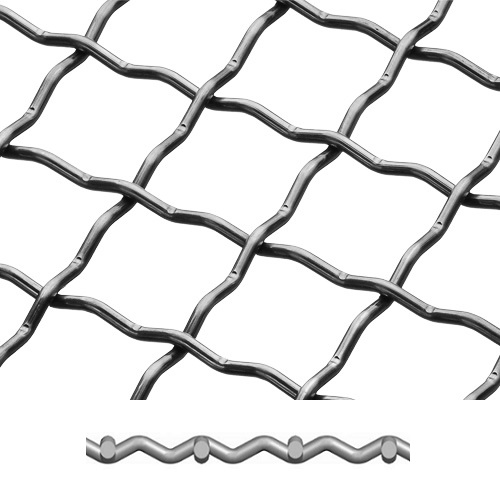

Double Crimped Wire Mesh Process

In this approach, wires are double crimped at each intersection prior to weaving, offering enhanced stability. This technique secures the wires firmly, ensuring a tight and uniform weave. It boasts greater strength and rigidity than plain crimped mesh, leading to a sturdier and more durable product. This mesh is particularly well-suited for heavy-duty tasks like rock crushing, mining, and industrial sieving, where a strong and stable mesh is essential.

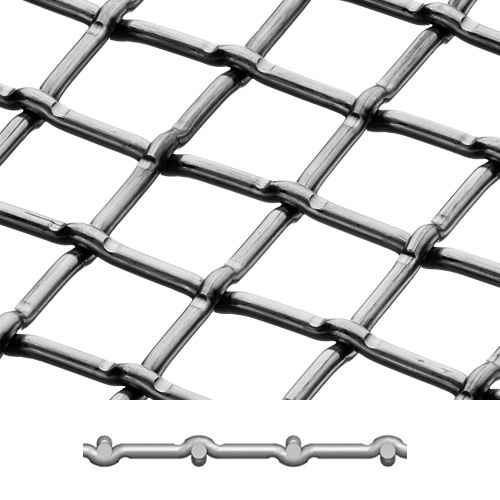

Flat Top Crimped Wire Mesh Process

This process crimps the wires such that one side of the mesh is flat, while the other side displays the crimps. This is achieved through a specialized crimping technique. The flat top design minimizes wear and tear on materials interacting with the mesh, ensuring smoother contact. This mesh is ideal for scenarios where material movement is crucial, such as on conveyor belts, and in architectural designs where a flat surface appearance is preferred.

Lock Crimped Wire Mesh Process

Lock crimped mesh involves deeply crimping the wires at each intersection, ‘locking’ them in place before weaving. This method produces a unique crimping pattern that enhances structural integrity. Renowned for its high stability and strength, lock crimping ensures a secure, non-shifting framework. It’s frequently utilized in architectural applications, heavy-load bearing panels, and scenarios where both aesthetic appeal and durability are essential.

Features

- Vandal Resistance: Exhibits resilience against damage and tampering, ensuring longevity.

- Low Maintenance: Requires minimal upkeep due to its sturdy nature and resistance to wear.

- Strong and Reliable: Offers dependable security, suitable for protective purposes.

- Simple Structure: Its straightforward design contributes to an aesthetically pleasing appearance.

- Easy Installation: Can be installed effortlessly, enhancing its suitability for various projects.

- Convenient Transport: Lightweight and easy to handle, facilitating transportation and handling.

Applications

- Industrial Screening: Used in industries for screening coal, sand, rock, ore, and other minerals.

- Agricultural Use: Serves in the separation and processing of crops and grains.

- Filtration: Effective in filtering applications in petroleum, chemical, acid, and alkali environments.

- Security Netting: Acts as a robust security net or fence in residential, commercial, and industrial areas.

- Architectural Applications: Utilized in architectural designs for facades, cladding, and decorative features.

- Ventilation and Airflow: Ideal for use in systems requiring good ventilation while maintaining security.

- Animal Enclosures: Used in zoos and farms for making animal enclosures, ensuring safety and visibility.

Product Photo Showcase and Alias

Crimped Woven Mesh

Ideal for architectural applications, this type accentuates the aesthetic appeal and functionality of the mesh, used in facades, decorative panels, and interior design elements.

Crimped Architectural Mesh

Focused on design and aesthetics, this mesh is used extensively in architectural elements, combining visual appeal with functional benefits in cladding, facades.