JD Hardware Wire Mesh Co., Ltd specializes in manufacturing and exporting high-quality Stainless Steel Wire Cloth for various industrial applications. Our product is known for its precision, with uniform, micron-sized mesh openings that guarantee consistent performance. Its robustness, high bearing, and tensile strength ensure it meets the stringent standards of multiple industries, emphasizing quality, reliability, and durability.

Weaving Type

Our Stainless Steel Wire Cloth comes in a variety of weaving styles, each tailored to specific applications and offering unique benefits:

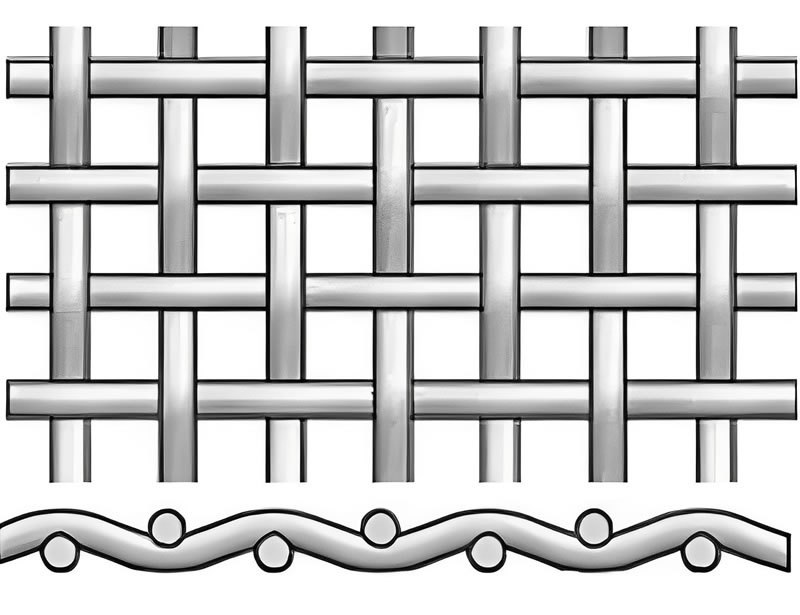

- Plain Weave: Plain weave is the most straightforward and widely used weaving style. In this method, each warp wire alternates over and under each weft wire, forming a uniform and sturdy structure. This weave provides high precision filtering with a maximum of 400 mesh, making it ideal for various screening and filtration applications.

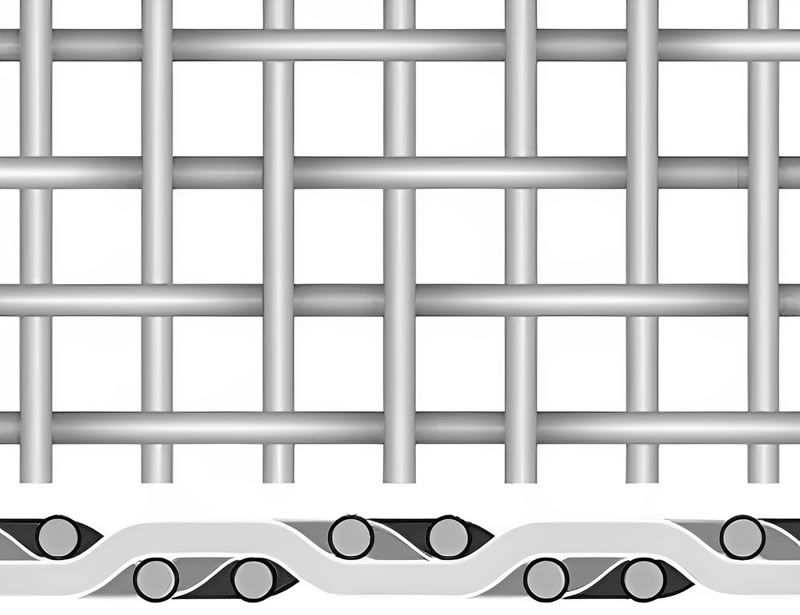

- Twill Weave: The twill weave pattern involves each weft or warp wire passing over two and under two successive wires. This design accommodates heavier wires and higher mesh counts, up to 635 mesh, enabling finer filtration. It’s especially effective for demanding applications requiring precision filtering under heavy loads and high pressure.

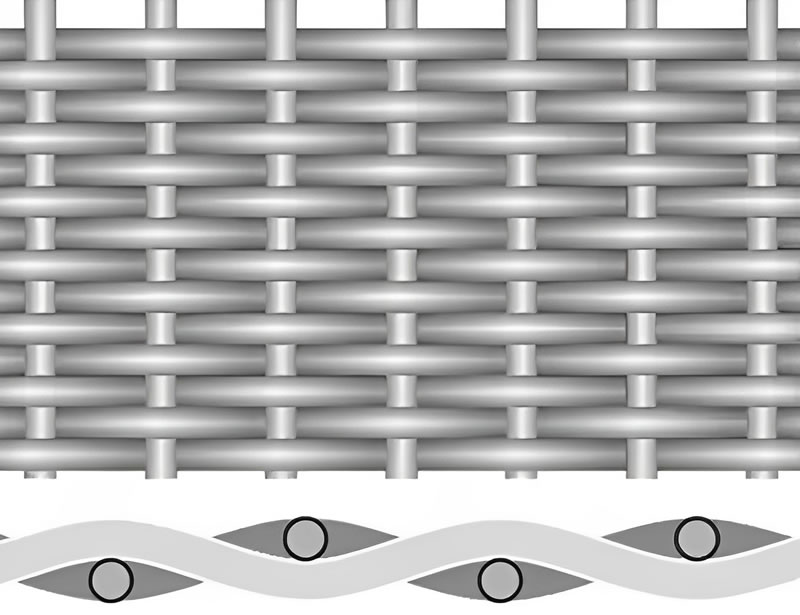

- Plain Dutch Weave: The Plain Dutch Weave is distinguished by its tight weave, utilizing thinner warp wires and thicker weft wires. This structure facilitates fine filtration, making it a go-to choice for applications that require precise separation. Excelling in superior fine filtration, the Dutch weave can achieve up to 500 × 3200 mesh, catering to highly specialized industrial processes where meticulous filtering is crucial.

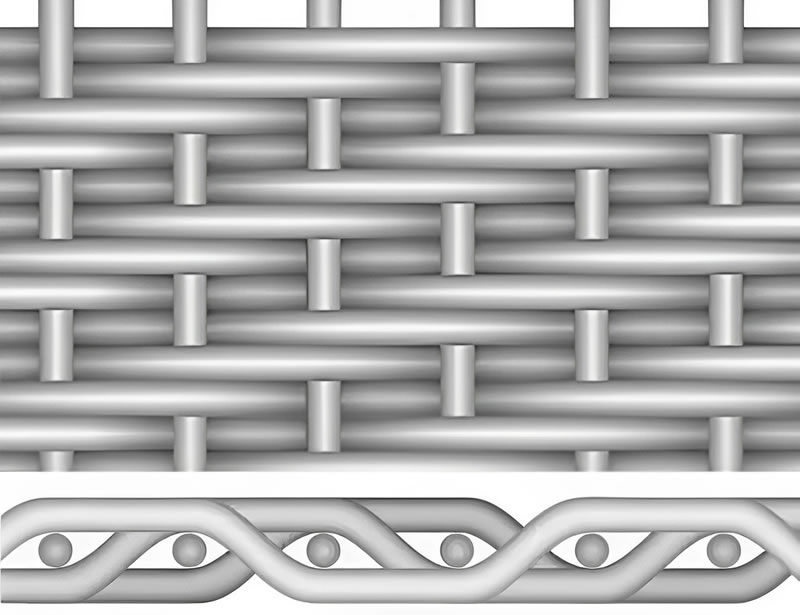

- Twill Dutch Weave: This style combines the methods of twill and dutch weaves. It features a tightly woven structure, providing excellent strength and fine filtration capabilities. It’s particularly effective for high-pressure filtration processes.

- Reverse Dutch Weave: The reverse dutch weave has finer warp wires and coarser weft wires. This structure is sturdy and can handle high pressure, making it ideal for applications such as plastic extrusion filtering.

- Five-Heddle Weave: This intricate weave pattern offers smooth surface on one side and a rough surface on the other. It’s known for its high flow rates and excellent cleaning ability, making it suitable for applications where efficient filtration and easy cleaning are required.

- Crimped Weave: Before weaving, the warp and weft wires are crimped or bent at regular intervals. This method is used to create a robust cloth with larger openings and is commonly employed in applications that require a sturdy structure, such as in architectural designs and fencing.

Each of these weaving types imbues our Stainless Steel Wire Cloth with distinct characteristics, ensuring we can provide solutions tailored to a wide range of industrial requirements.

Common Specification

- Material Composition: Diverse Stainless Steel Varieties

Our Stainless Steel Wire Cloth is made from several grades of stainless steel, including 304, 304L, 316, 316L, 310, 314, 410, and 430. This variety ensures that we can provide the perfect match for your specific application, whether you require the corrosion resistance of 316 or the heat resistance of 310. - Wire Diameter: Precision and Flexibility

The wire diameters we offer range from 0.02 to 0.15 mm, allowing for a broad spectrum of strength and flexibility to suit various industrial needs. This range ensures precise control over filtration and screening processes. - Aperture Size: Versatile Range for Diverse Applications

Our Stainless Steel Wire Cloth is available in a comprehensive range of aperture sizes to cater to various industrial needs. These sizes range from larger openings suitable for robust screening down to smaller apertures ideal for precision filtration. The common range spans from larger sizes, around 4 mm, suitable for heavy-duty applications, down to finer sizes, as small as 25 microns, for high-precision tasks. This versatility ensures our wire cloth can be effectively utilized in a wide array of scenarios, from straightforward sorting to intricate filtering processes. - Roll Dimensions: Convenient Sizes

We provide our Stainless Steel Wire Cloth in rolls, with a standard width of 1 meter or 48 inches and a length of 30 meters or 100 feet. This makes handling and installation efficient and adaptable to various project sizes.

Features

- Robust Strength and Tensile Properties: Exhibits high bearing capacity and tensile strength, suitable for demanding applications.

- Precision in Filtration: Known for its high filter precision, it efficiently separates and filters various substances.

Resilience to Acids, Alkalis, and Heat: Resistant to acids, alkalis, heat, and chemicals, making it a versatile choice. - Resistance to Abrasion: Well-suited to withstand wear and tear, ensuring longevity.

- Aesthetically Pleasing Appearance: Boasts a cleaner and brighter look, enhancing its suitability for visible applications.

Applications

Stainless Steel Wire Cloth’s unique blend of features like high strength, precision, and resistance to harsh conditions makes it an indispensable tool across multiple industries, from heavy-duty industrial to delicate biomedical applications.

- Versatile Industry Use: Essential in petroleum, chemical, electronic, textile, ceramic, glass, and biomedical sectors.

- Diverse Functionalities: Ideal for filtering, protection, feeding, decoration, and printing applications.

- Architectural and Residential Applications: Its durability and aesthetic appeal make it a choice material in architecture and home design.

- Petroleum Industry: Particularly useful as a shaker screen and in various filtering tasks like oil-water and gas-liquid separation.

- Biomedical Field: Its inert and non-reactive nature makes it suitable for sensitive biomedical applications.

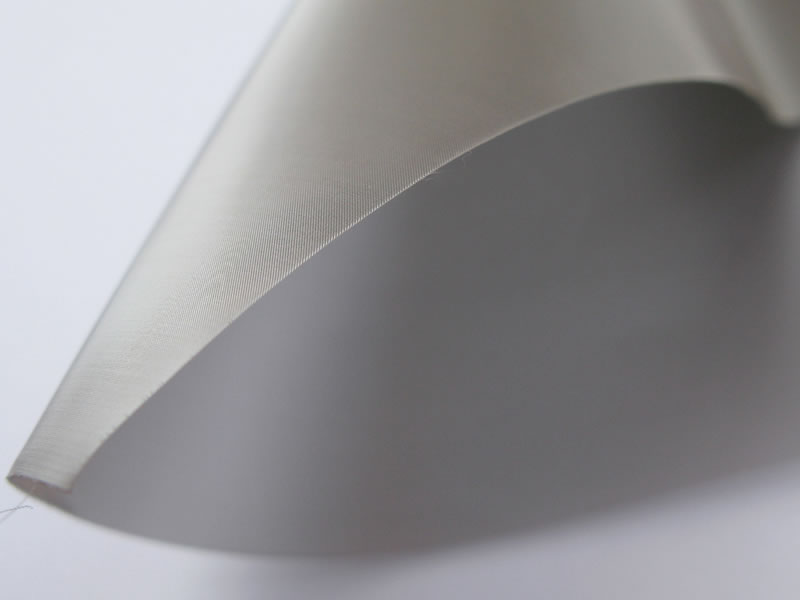

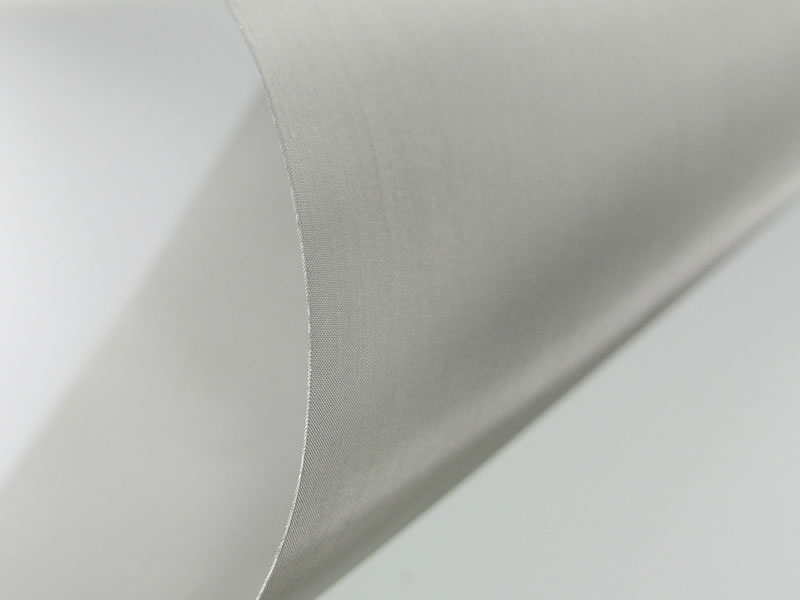

Product Photo Showcase and Alias

Stainless Steel Screening Cloth: This cloth is ideal for screening processes due to its even mesh openings that guarantee both efficiency and precision. It is widely chosen for filtration and sieving across various industrial applications.

Stainless Steel Sieve Cloth: This cloth, tailored for sieving, ensures high accuracy and consistency in its use. It is a common choice in both laboratory and industrial environments for effective material separation and particle size analysis.

Stainless Steel Shaker Screen: Specially crafted for high-intensity vibration in oil and gas operations, this screen is adept at separating drilling mud and solids from fluids. Its durable design and resistance to corrosion make it perfect for these rigorous applications.

Stainless Steel Filtration Cloth: Focusing on filtration applications, this cloth offers superior efficiency in filtering. It is extensively utilized in the chemical, food, and pharmaceutical sectors for the purification and separation of liquids and gases.