JD Hardware Wire Mesh Co., Ltd, specialize in the manufacturing of Reverse Dutch Weave Stainless Steel Wire Mesh, a product designed for efficient and reliable filtration. Our mesh is primarily made from high-quality stainless steel wire, known for its excellent resistance to various chemicals, acids, alkalis, rust, and corrosion. This ensures the durability and long-term effectiveness of our mesh in filtration processes. We also offer a variant made from brass wire, which shares the same chemical stability, making it suitable for filtration.

Our production process involves intricately weaving stainless steel or brass wires into a reverse dense weave pattern using two different wire diameters. This unique construction makes our mesh highly sought after in various sectors. It is particularly useful in the petrochemical and aerospace industries for creating filter discs and a range of other filtration products. At JD Hardware Wire Mesh Co., Ltd, we are committed to delivering quality and functionality in all our products.

Specifications

Material Options

- SUS302: Ideal for general applications, offering good corrosion resistance.

- SUS304: Known for its excellent corrosion and oxidation resistance, suitable for a variety of environments.

- SUS316: Offers superior corrosion resistance, ideal for marine or high-chloride environments.

- SUS316L: Lower carbon version of SUS316, providing enhanced resistance to corrosion and oxidation.

Mesh Count Range

- From 54mesh*15mesh: Provides finer filtration, suitable for precise applications.

- Up to 350mesh*40mesh: Offers coarser filtration, ideal for heavier or larger particle separation.

Wire Diameter Variations

- Starts at 0.13mm*0.27mm: Thin wire diameters for delicate, precise filtration needs.

- Extends to 0.45mm*0.6mm: Thicker wire diameters for enhanced durability and strength in filtration.

Thickness Availability

- Minimum thickness: 0.6mm: Thin and lightweight, ideal for less demanding applications.

- Maximum thickness: 1.75mm: Thick and robust, suitable for more strenuous or heavy-duty filtration tasks.

Weave Patterns

- Plain Reverse Dutch Weave Woven Wire Mesh: Standard weave pattern offering balanced filtration efficiency.

- Twill Reverse Dutch Weave Woven Wire Mesh: Provides a tighter weave, enhancing filtration accuracy for finer particles.

Customization Capabilities

- Our Reverse Dutch Weave Stainless Steel Wire Mesh is adaptable to a wide range of requirements. Clients can specify mesh counts, wire diameters, and thicknesses to suit specific filtration needs. This flexibility allows for optimal performance in diverse applications, from delicate laboratory settings to rugged industrial environments.

| Mesh counts | Wire diameter(mm) | Thickness(mm) | Width(mm) |

| 54*15 | 0.45*0.6 | 1.75 | 50——800 |

| 72*15 | 0.45*0.55 | 1.7 | 50——800 |

| 132*17 | 0.23*0.45 | 1.2 | 50——1000 |

| 160*18 | 0.28*0.45 | 1.27 | 50——1000 |

| 200*40 | 0.17*0.27 | 0.7 | 50——1500 |

| 260*40 | 0.15*0.27 | 0.65 | 50——1500 |

| 300*40 | 0.13*0.27 | 0.65 | 50——1500 |

| 350*40 | 0.13*0.27 | 0.6 | 50——1500 |

Note: Special size and specification can be customized.

Features

- High-Quality Material: Constructed from high-strength stainless steel wire, ensuring durability and long-term use.

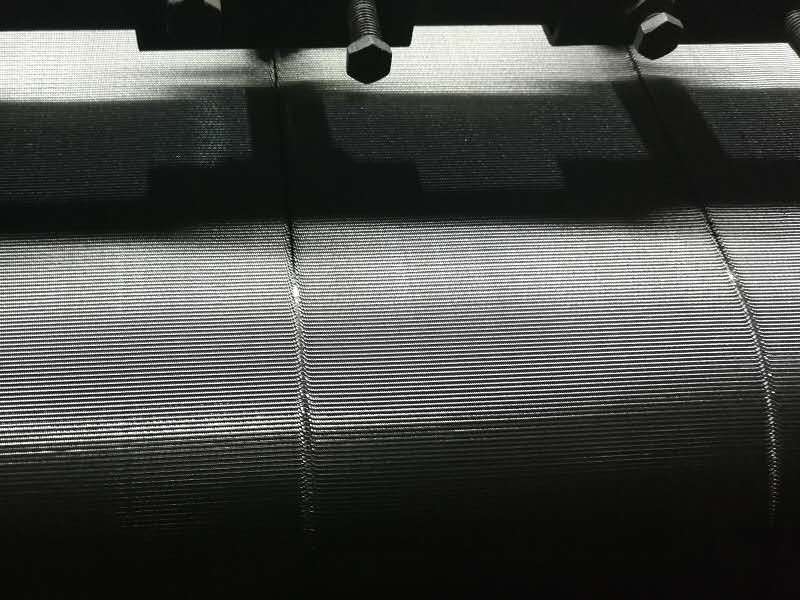

- Advanced Manufacturing: Utilizes state-of-the-art equipment and sophisticated production technology.

- Surface and Structure: Characterized by a smooth surface and high hardness, with a consistent net structure that resists deformation.

- Resilience: Capable of withstanding high temperatures and resistant to corrosion.

- Superior Filtration Performance: Excelling in filtering capabilities, making it an effective and reliable option.

Applications

- Broad Industrial Use: Essential in industries for sifting grainy materials, powders, and in filtration processes for liquids and gases.

- Mining: For sorting and processing minerals.

- Oil and Chemicals: Used in filtering processes.

- Food and Pharmaceuticals: Critical in quality control and production processes.

- Machinery Manufacturing: Integral in the construction and functioning of machinery.

- Scientific Research: Utilized in experimental setups and research projects.

- Aviation: Applied in various aviation-related manufacturing and maintenance tasks.

- Versatility: Its wide range of applications highlights its adaptability and utility across different fields and purposes.

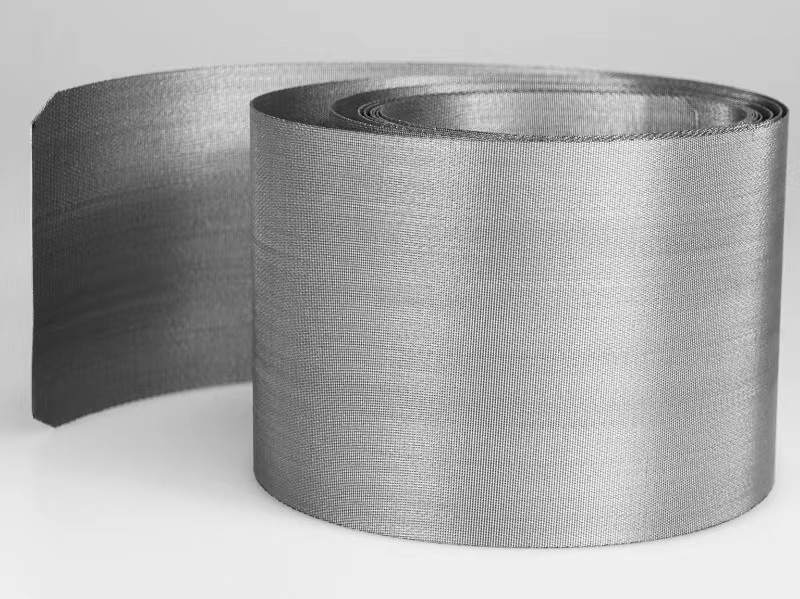

Product Photo Showcase and Alias

Dutch Reverse Weave Wire Mesh

Introduction: Optimized for high-strength and precision, this mesh variant is ideal for effective particle separation in various filtration processes. Its reverse Dutch weave technique makes it suitable for industries where strength and precision are crucial, such as water treatment and fine particulate filtration.

Stainless Twill Reverse Dutch Mesh

Introduction: Featuring a twill weave pattern, this mesh excels in demanding filtration scenarios. Its double-directional weave enhances filtration efficiency, making it a top choice in sectors requiring both strength and precision, like chemical processing and advanced material manufacturing.

Fine Reverse Dutch Weave Wire Mesh

Introduction: With a focus on fine, tight weaving, this mesh is perfect for precise filtration needs. It’s particularly effective in pharmaceutical and chemical industries where meticulous particle separation is essential, including in the production of fine chemicals and medical filters.

Heavy-Duty Reverse Dutch Weave Mesh

Introduction: Designed for industrial strength and durability, this mesh is a staple in heavy-duty applications. It’s extensively used in mining, oil, and construction industries, where robust materials are vital for effective filtration under harsh conditions.

Reverse Dutch Wire Cloth Fabric

Introduction: Balancing flexibility and strength, this mesh variant is versatile for diverse filtration systems. Its cloth-like flexibility coupled with a strong structure makes it ideal for custom filtration solutions in industries like automotive and aerospace engineering.

Precision Reverse Dutch Mesh

Introduction: This high-performance mesh is tailored for exact filtration requirements. It’s particularly beneficial in scientific research and high-tech manufacturing, where precise filtration is imperative, such as in laboratory experiments and electronics production.