JD Hardware Wire Mesh Co., Ltd specializes in the manufacture and export of Temporary Conical Strainers, widely recognized for their crucial role in coarse filtration within medium conveying pipes. These strainers, also known as witch’s hat or temporary cone strainers, are fundamental components in maintaining the purity of pipeline mediums, thereby ensuring the smooth and safe operation of various industrial systems.

Designed for optimal efficiency, our conical strainers are typically positioned at the inlet ports of various types of valves, including relief valves, decompression valves, and water level valves. Their primary function is to meticulously filter out impurities from the medium, permitting only the clean fluid to traverse through their finely constructed mesh screens. This process is pivotal in safeguarding equipment from potential damage caused by particulate matter and in promoting stable process flows within industrial setups.

One of the standout features of our Temporary Conical Strainers is the ease of maintenance they offer. The design includes a removable cartridge which simplifies the cleaning process. Users can effortlessly remove, cleanse, and reinstall the cartridge, ensuring the strainer remains functional and effective with minimal downtime. This user-friendly design aspect underscores our commitment to providing practical, efficient, and reliable solutions to our customers.

Material Options

Our Temporary Conical Strainers are crafted from high-quality materials, including Stainless Steel grades 304, 304L, 316, 316L, and Monel, with other alloys available upon request. This selection ensures durability and compatibility with various industrial environments and mediums.

Filter Media Construction

These strainers are offered in a range of configurations:

- Perforated metal for robust filtration.

- Woven wire mesh for fine filtration.

- A combination of perforated metal outside with woven mesh inside, or the reverse, for enhanced efficiency.

- Designs featuring internal wire support and external woven wire mesh. These varied configurations cater to specific filtration needs.

Layer Customization

This flexibility allows customization for specific filtration effectiveness and strength. Options for layering include:

- Single-layer perforated metal mesh without inner wire cloth.

- Single-layer wire cloth.

- Multilayer wire cloth for intricate filtration demands.

Size and Type Variability

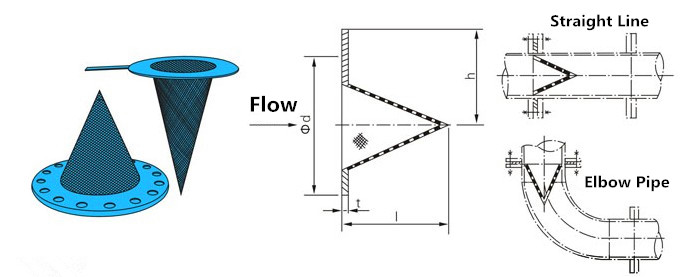

Both types are designed to fit a variety of piping systems, with commonly used sizes readily available. Custom sizes can also be provided to meet specific installation and filtration needs. Available in two primary types:

- V bottom cone temporary strainers, ideal for focused filtration, available in diameters of 2″, 4″, 6″, 8″, and 10″.

- Flat bottom cone temporary strainers, suitable for broader applications, available in sizes including 3″, 5″, 7″, 9″, and 12″.

Temporary Conical Strainers Features

- Streamlined Filtration Design: Belonging to the coarse filtration series, these strainers have a simplistic yet efficient design, making them ideal for straightforward installation and operation in various pipeline systems.

- Hassle-Free Maintenance: Their user-friendly design allows for effortless removal and reinstallation, which is particularly advantageous during routine cleanings. This feature ensures minimal downtime and disruption to ongoing processes.

- Stainless Steel Durability: Constructed with high-quality stainless steel, Temporary Conical Strainers are highly resistant to corrosion. This material choice extends their service life significantly, making them a reliable choice in harsh industrial environments.

- Optimized for Coarse Filtration: Specially designed for filtering larger particles, these strainers are an essential component in protecting equipment from potential clogging and damage, thereby ensuring smoother operations.

- Long-Term Reliability:

The durability and ease of maintenance of these strainers translate into long-term reliability, reducing the need for frequent replacements and thereby offering cost-effective filtration solutions.

Applications of Temporary Conical Strainers

- Filtration Principle: These strainers operate on a simple yet effective principle: as fluid enters the conical filter, impurities are trapped, allowing only clean fluid to exit through the outlet. This process ensures efficient removal of contaminants.

- Pipeline Medium Purification: They play a crucial role in removing impurities from various mediums in pipelines. This not only helps in the normal functioning of equipment but also contributes to maintaining stable processes and ensuring the safety of equipment during production.

- Industrial Usage: Temporary Conical Strainers are predominantly used in industries involving processing of solid particles. They are essential in pharmaceutical, chemical, pesticide, and food industries, particularly for processes like boiling, drying, conveying, and filtering. Their effectiveness in these applications makes them a vital component in ensuring product quality and process reliability.

Product Photo Showcase and Alias

Pharmaceutical Grade Strainers: Designed for use in pharmaceutical applications, where cleanliness and material compatibility are crucial.

Industrial Grade Strainers: More robust, suitable for industrial applications involving harsher conditions or more abrasive materials.

Standard Cone Strainers: Traditional conical shape, ideal for general use.

Coarse Mesh Strainers: Designed for larger particles, typically used in applications where finer filtration is not critical.

Fine Mesh Strainers: Suitable for filtering smaller particles, used in applications requiring more precise filtration.

Flat Bottom Strainers: Provide stability and are often used in applications where the strainer needs to stand independently.

V-Bottom Strainers: Allow for more efficient drainage and are typically used in applications where quick filtration is necessary.