JD Hardware Wire Mesh Co., Ltd specializes in producing and exporting Temporary Plate Strainers, also known as disk type or gasket strainers. These strainers are meticulously crafted from wire mesh, perforated metal, or a blend of both, and are designed for installation between standard pipeline flanges. They play a vital role in protecting downstream equipment during initial startups and regular operations.

Although they have a smaller filtration surface area compared to cone or basket strainers, JD Hardware’s Temporary Plate Strainers are renowned for their easy installation and removal, a feature that is especially advantageous in environments requiring quick access and efficiency.

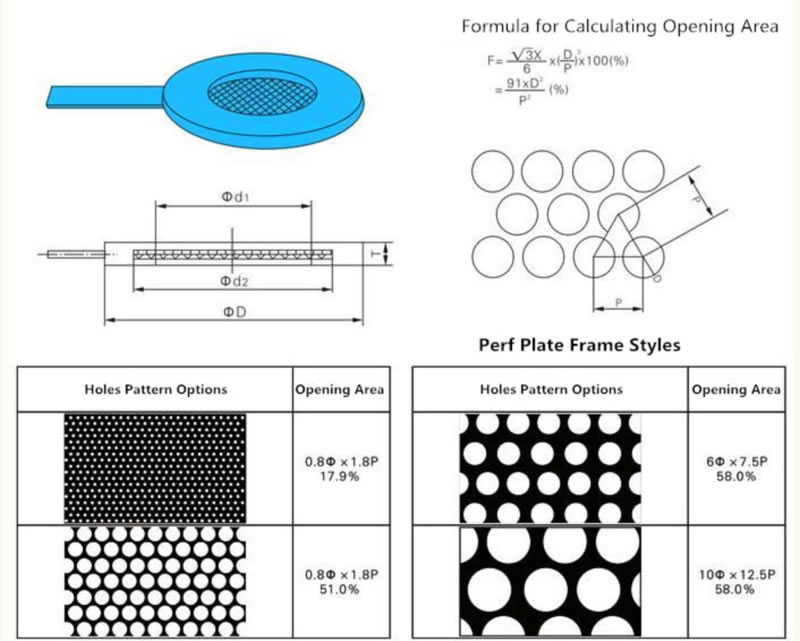

Our product line covers a wide range of sizes, from DN 3/4” to 24”, to suit various industrial needs. With perforation choices from 3/32” to 1/4” and mesh sizes from 4 to 100, these strainers can be precisely tailored to specific filtration needs. Constructed mainly from plain steel or stainless steel, they ensure both durability and versatility in different applications.

Material Options

JD Hardware Wire Mesh Co., Ltd offers Temporary Plate Strainers in various materials to meet diverse industrial needs. Available options include durable Stainless Steel grades 304, 304L, 316, 316L, and Monel, with the possibility of supplying other alloys upon request to ensure compatibility with a range of industrial conditions.

Design and Shape

Our strainers are designed as flat plate strainers, facilitating easy installation and removal in pipeline systems. This flat design is particularly beneficial for applications with space limitations or specific flow requirements.

Filter Media Varieties

These options allow for precise filtration tailored to specific operational demands. Customers can select from various filter media configurations:

- A Single layer of perforated metal mesh for robust filtration.

- Single-layer wire cloth for more refined filtration.

- Multilayer wire cloth for complex filtration needs.

Size Range and Customization

We offer Temporary Plate Strainers in common sizes suitable for standard pipeline dimensions, as well as custom sizes to fit unique system requirements. Our standard size range includes:

- Small sizes such as 2”, 4”, and 6” for smaller pipeline systems.

- Medium sizes like 8”, 10”, and 12” for moderate applications.

- Large sizes up to 24” for extensive industrial systems.

- The customization also extends to the filter media, with perforation sizes ranging from fine to coarse and wire mesh densities varying based on specific needs.

- Dimensions for temporary plate strainer

| NPS | B Inside diameter | A(Outside diameter) (Class 150-1500) | ||||

| 150 | 300 | 600 | 900 | 1500 | ||

| 3/4 | 19 | 54 | 64 | 64 | 67 | 67 |

| 1 | 25 | 64 | 70 | 70 | 76 | 76 |

| 1-1/2 | 38 | 83 | 92 | 92 | 95 | 95 |

| 2 | 51 | 102 | 108 | 108 | 140 | 140 |

| 2-1/2 | 64 | 121 | 127 | 127 | 162 | 162 |

| 3 | 76 | 133 | 146 | 146 | 165 | 171 |

| 4 | 102 | 171 | 178 | 183 | 203 | 206 |

| 5 | 127 | 194 | 210 | 238 | 244 | 251 |

| 6 | 152 | 219 | 248 | 264 | 286 | 279 |

| 8 | 203 | 276 | 305 | 318 | 356 | 349 |

| 10 | 254 | 337 | 359 | 397 | 432 | 432 |

| 12 | 305 | 406 | 419 | 454 | 495 | 518 |

| 14 | 337 | 441 | 479 | 483 | 518 | 575 |

| 16 | 387 | 511 | 533 | 556 | 572 | 638 |

| 18 | 438 | 540 | 587 | 603 | 635 | 702 |

| 20 | 489 | 597 | 648 | 676 | 695 | 752 |

| 24 | 591 | 708 | 768 | 784 | 835 | 899 |

Applications of Temporary Plate Strainers

- Versatile Industrial Use: Temporary Plate Strainers are integral in a wide range of industrial applications. Their primary function is to filter out foreign particles, ensuring smooth and efficient production processes.

- Power Generation: In power plants, they are crucial for keeping fluid systems free from contaminants, aiding in reliable power generation.

- Maritime Operations: Essential in marine applications, these strainers protect engines and systems from particle damage.

- Oil and Gas Industry: Used extensively to purify fluids in oil and gas exploration and processing, enhancing safety and efficiency.

- Water and Sewage Treatment: In water treatment facilities and sewage systems, they prevent clogging and ensure operational efficiency.

Features of Temporary Plate Strainers

- Ease of Installation and Cleaning: These strainers are designed for effortless setup and maintenance, allowing for quick installation and straightforward cleaning processes.

- Simple Manufacturing and Cost-Effectiveness: The straightforward design of Temporary Plate Strainers ensures ease of manufacture, contributing to their affordability. This makes them a cost-efficient choice for various industrial applications.

- Low Maintenance Requirements: With their durable design, these strainers require minimal upkeep, reducing the frequency and cost of maintenance.

- Durable Material with Longevity: Constructed from stainless steel, Temporary Plate Strainers boast high corrosion resistance, ensuring a prolonged service life even in challenging industrial environments.

Product Photo Showcase and Alias

Industrial Processing Temporary Plate Strainers: Used extensively in various manufacturing and processing industries to remove debris from liquids and gases, ensuring the smooth operation of machinery and equipment.

Water Treatment Temporary Plate Strainers: Utilized in water treatment facilities to filter out sediments and impurities, ensuring the cleanliness and safety of water for various uses.

Oil and Gas Industry Temporary Plate Strainers: Critical in the oil and gas sector for removing particles from oils and gases during exploration, refining, and distribution processes.

Chemical Plant Temporary Plate Strainers: Employed in chemical processing plants to filter out contaminants from chemical flows, thus protecting equipment and ensuring product purity.