Our Sintered Stainless Steel Wire Mesh is characterized by its uniform pore sizes and exceptional filtration capabilities. We predominantly use high-grade stainless steel, including 316L, 316, 304, and 304L, selected for their remarkable mechanical strength, resistance to corrosion, and ability to withstand high temperatures. These features render our mesh suitable for a broad spectrum of industrial uses.

While alternative materials like bronze, nickel alloys, and titanium are available options, stainless steel is our material of choice. It stands out for its endurance, chemical stability, and the flexibility of being offered in various grades to cater to a range of operational needs. JD Hardware Wire Mesh Co., Ltd is committed to providing high-quality, reliable, and versatile sintered wire mesh solutions to meet the diverse requirements of our clients.

Varieties of Sintered Mesh Filters

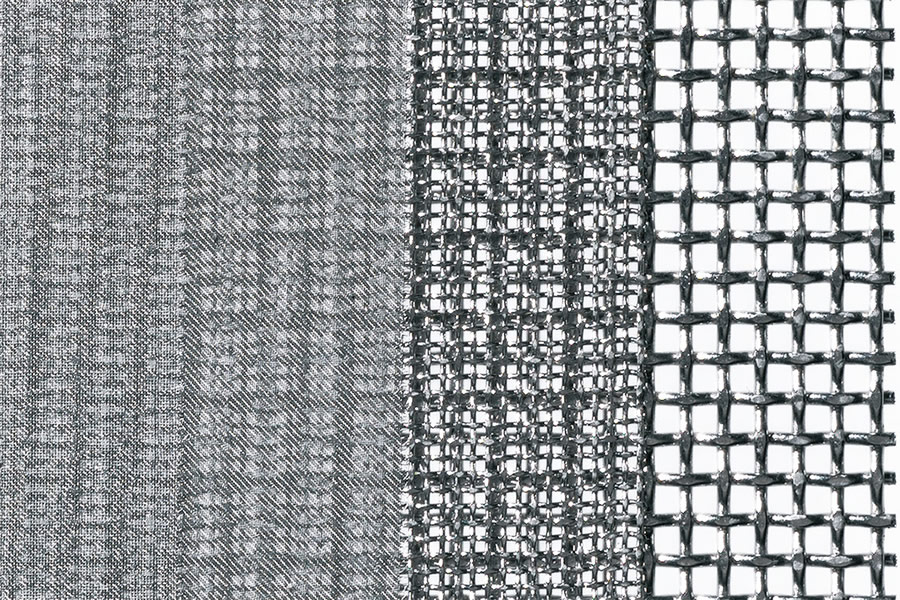

- Single-layer Sintered Mesh: This category features a sintered wire mesh made from a singular layer. It provides basic filtration and is ideal for scenarios needing rudimentary, coarse filtering.

- Multi-layer Sintered Mesh: Comprising several layers of sintered wire mesh, this type is structured with each successive layer being finer than the last. The coarser layers serve as a foundation, while the finer ones execute more precise filtration. This variety is adept at enhanced filtration tasks and is well-suited for situations that demand detailed, fine filtering.

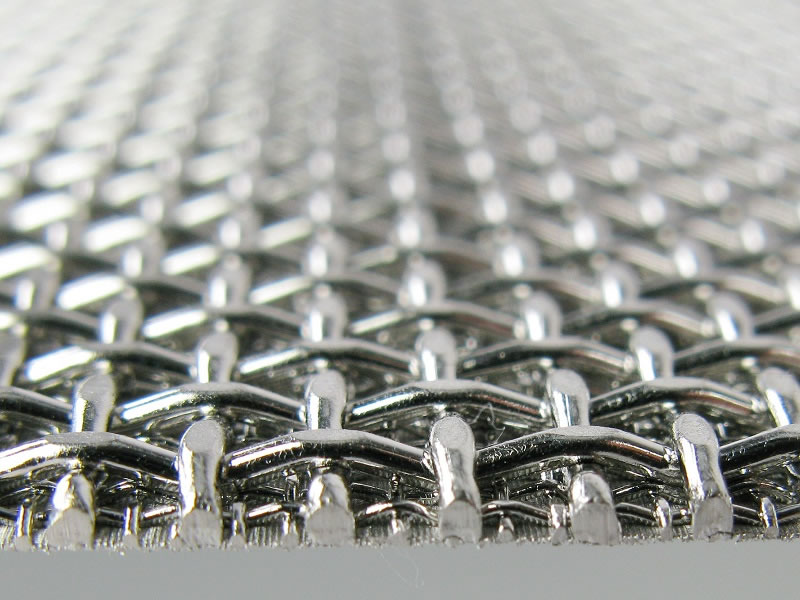

- Sintered Mesh Structure: Sintered mesh is typically designed with 2 to 5 layers, offering variability in its composition. The number of these layers is pivotal in determining the effectiveness of the mesh’s filtration capabilities as well as its overall structural strength.

Filter Precision / Filtration Grade

- The multi-layered structure of sintered mesh enables it to achieve superior filtration precision, thanks to its sequentially finer mesh layers. This design allows for filtration rates that span from ultra-fine, sub-micron levels (less than 1 μm) to several hundred microns. Such a range makes multi-layer sintered mesh ideal for applications requiring accurate and effective filtration of fine particles.

Support Layers in Sintered Mesh

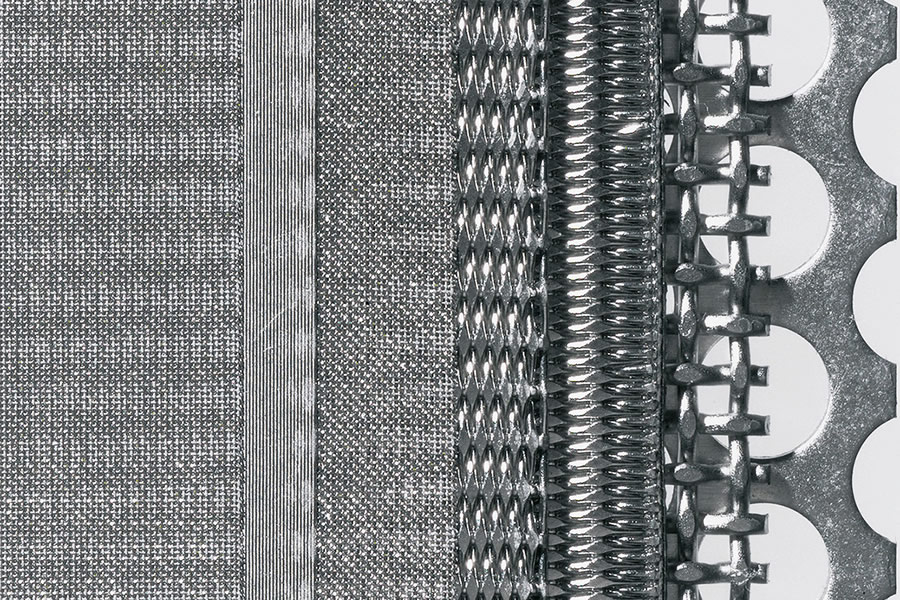

Sintered mesh typically includes one of two main types of support layers to enhance its strength and durability:

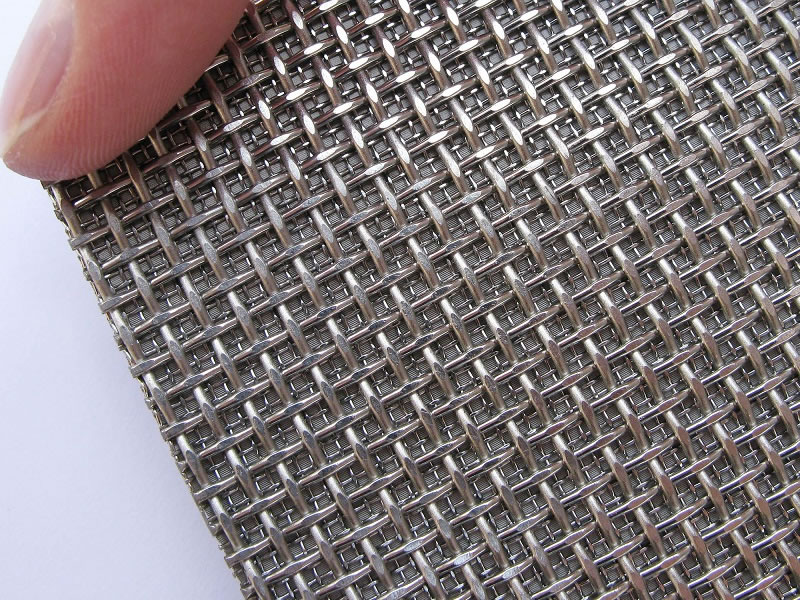

- Crimped Wire Mesh Layer: This involves an extra layer of crimped, woven wire mesh with larger wire diameters integrated into the sintered mesh structure. Positioned on either one or both sides of the sintered mesh, this crimped wire mesh layer significantly boosts the mesh’s mechanical strength and stability, enhancing its ability to resist pressure and impact.

- Perforated Metal Layer: In this variation, a perforated metal plate, often crafted from stainless steel, is attached to one or both sides of the sintered mesh. The perforated metal reinforcement bolsters the structural integrity of the mesh, making it more resilient and enduring. It is particularly beneficial in scenarios where the sintered mesh is subjected to high pressures, mechanical strains, or needs to maintain its shape under stress.

5-Layer Sintered Wire Mesh Filter Specifications

- Nominal Filter Rating: The 5-layer sintered wire mesh filter offers a range of nominal filter ratings to accommodate various filtration requirements. Common ratings include 1 µm, 5 µm, 10 µm, 20 µm, and 200 µm. These ratings ensure precise particle size control, making the filter versatile for different applications.

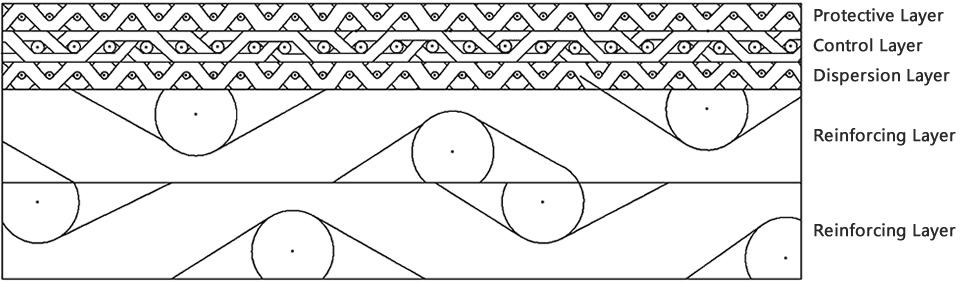

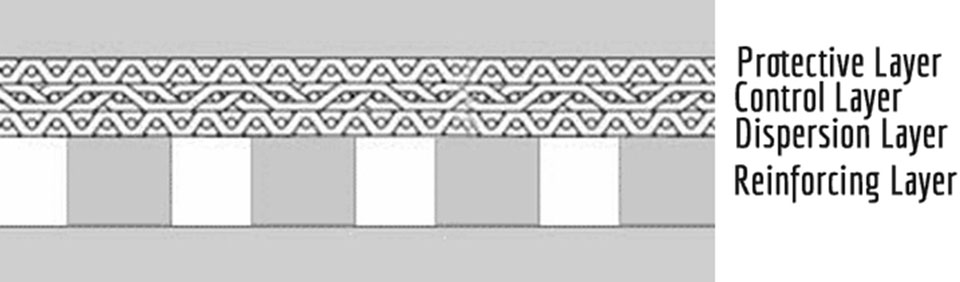

- Structure: This filter comprises five distinct layers: a Protective Layer, a Control Layer, a Dispersion Layer, and two Reinforce Layers. This multi-layered structure enhances filtration efficiency and structural integrity, providing both fine filtration and durability.

- Thickness: The standard thickness of the 5-layer sintered wire mesh filter is typically around 1.7 mm. This thickness is optimal for balancing effective filtration with necessary structural support.

- Air Permeability:

Air permeability for these filters is typically in the range of 1.81 to 9.1 L/min/cm², ensuring that the filter maintains adequate airflow while trapping particles effectively. - Bubble Pressure: The bubble pressure of the filter, a measure of its pore size and filtration capability, varies based on the nominal filter rating. It usually ranges from 360 to 600 mm H2O, reflecting its suitability for different filtration pressures.

- Weight: The weight of the 5-layer sintered wire mesh filter is standardized at 8.4 kg/m². This weight is a result of its robust construction, ensuring the filter’s strength and longevity in various applications.

- Size:

| Model No. | Nominal Filter Rating | Structure: Protective Layer + Control Layer + Dispersion Layer + Reinforce Layer + Reinforce Layer | Thickness | Air Permeability | Bubble Pressure | Weight |

| (µm) | (mm) | (L/ min/cm2) | (mm H2O) | (kg/m2) | ||

| JD-1/5 | 1 | 100 + 400×2800 + 100 + 12×64 + 64×12 | 1.7 | 1.81 | 360-600 | 8.4 kg/m2 |

| JD-2/5 | 2 | 100 + 325×2300 + 100 + 12×64 + 64×12 | 1.7 | 2.35 | 300-590 | |

| JD-5/5 | 5 | 100 + 200×1400 + 100 + 12×64 + 64×12 | 1.7 | 2.42 | 260-550 | |

| JD-10/5 | 10 | 100 + 165×1400 + 100 + 12×64 + 64×12 | 1.7 | 3 | 220-500 | |

| JD-15/5 | 15 | 100 + 165×1200 + 100 + 12×64 + 64×12 | 1.7 | 3.41 | 200-480 | |

| JD-20/5 | 20 | 100 + 165×800 + 100 + 12×64 + 64×12 | 1.7 | 4.5 | 170-450 | |

| JD-25/5 | 25 | 100 + 165×600 + 100 + 12×64 + 64×12 | 1.7 | 6.12 | 150-410 | |

| JD-30/5 | 30 | 100 + 450 + 100 + 12×64 + 64×12 | 1.7 | 6.7 | 120-390 | |

| JD-40/5 | 40 | 100 + 325 + 100 + 12×64 + 64 × 12 | 1.7 | 6.86 | 100-350 | |

| JD-50/5 | 50 | 100 + 250 + 100 + 12×64 + 64 × 12 | 1.7 | 8.41 | 90-300 | |

| JD-75/5 | 75 | 100 + 200 + 100 + 12×64 + 64 × 12 | 1.7 | 8.7 | 80-250 | |

| JD-100/5 | 100 | 100 + 150 + 100 + 12×64 + 64 × 12 | 1.7 | 9.1 | 70-190 | |

| JD-150/5 | 150 | 50 + 100 + 50 + 30×30 + 100 × 50 | 2 | 25 | 50-150 | |

| JD-200/5 | 200 | 40 + 80 + 40 + 20×40 + 80 × 40 | 2 | 26 | 50-150 |

Characteristics of Stainless Steel Sintered Wire Mesh

- Robust Structural Integrity: This mesh is recognized for its exceptional mechanical robustness and consistent stability, making it reliable for various applications.

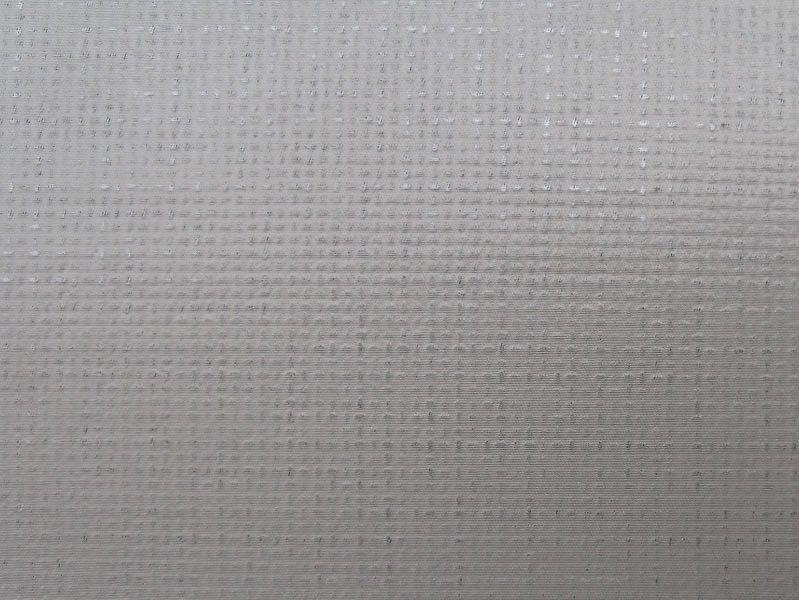

- Consistent Pore Distribution and Accurate Filtration: The mesh boasts evenly distributed pore sizes, ensuring precise and effective filtration.

- Enhanced Corrosion and Heat Resilience: It is notably resistant to corrosion and can withstand high temperatures, enhancing its suitability for challenging environments.

- Optimal Permeability with Minimal Pressure Reduction: The mesh facilitates good airflow while maintaining a low pressure drop, optimizing its efficiency.

- Maintenance-Friendly: Its design allows for straightforward cleaning and upkeep, contributing to its longevity and ease of use.

- Customizable Design Flexibility: The mesh can be tailored into diverse shapes and sizes, offering versatility to meet specific requirements.

Utilization of Stainless Steel Sintered Wire Mesh

- Chemical and Pharmaceutical Filtering: Employed extensively for the filtration of both liquids and gases in intricate chemical and pharmaceutical operations.

- Water Treatment and Purification: Plays a crucial role in the purification and treatment processes of water, ensuring safety and quality.

- Air Filtration in Automotive and Aerospace: Integral in the automotive and aerospace sectors, particularly for efficient air filtration systems.

- Oil and Gas Exploration and Refining: A key component in the oil and gas industry, utilized in various stages from well drilling to refining processes.

- Food and Beverage Industry: Essential in the processing stages within the food and beverage industry, maintaining quality and safety standards.

- Medical Applications: Vital in the healthcare realm, sintered wire mesh is used in a range of medical devices, including implants and surgical instruments, owing to its biocompatibility and durability.

- Environmental Protection: Instrumental in initiatives for environmental conservation, playing a significant role in pollution control and management.

Product Photo Showcase and Alias

Sintered Stainless Filter Mesh: Emphasizing its primary role in filtration applications, particularly in industries where purity and precision are paramount.

Stainless Steel Sintered Filter Cloth: Highlighting its cloth-like properties and adaptability, often used in applications requiring fine and uniform filtration.

Stainless Sintered Mesh Screen: This term accentuates its use as a screening material in various industrial processes, combining durability with fine meshing.

Metal Sintered Mesh Laminate: Suggesting its layered structure, this name is typically used in contexts where the mesh’s composite nature is a key feature.

Stainless Steel Mesh Laminate: Reflecting its layered, laminated structure, emphasizing the strength and durability of the mesh.

Sintered Stainless Steel Mesh Disc: Used when the mesh is cut or formed into disc shapes, commonly found in filtration assemblies.

Sintered Metal Mesh Panel: This term is used when the mesh is utilized in panel form, often in architectural or structural applications.

Sintered SS Wire Cloth: A variant focusing on the wire cloth aspect, commonly used in filtration and sieving applications.

Sintered Stainless Mesh Filter Element: Used specifically when the mesh is part of a larger filter assembly or system.

Stainless Steel Sintered Porous Mesh: This name emphasizes the porous nature of the mesh, highlighting its use in applications requiring permeability and filtration.